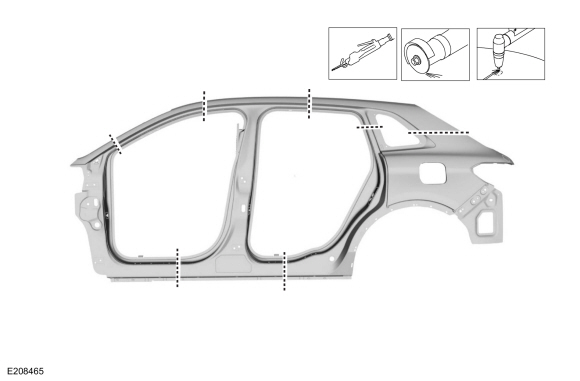

Lincoln Nautilus: Body Repairs - Vehicle Specific Information and Tolerance Checks / Body Panel Sectioning. General Procedures

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Repair

NOTICE: Do not begin removal of the vehicle body side until the replacement panel is available for reference.

NOTICE: Do not carry out body side sectioning repairs in areas of door hinge, safety belt or striker anchoring points. Welding within 50 mm (1.96 in) of door hinge or striker locations may compromise structural integrity during a collision.

NOTICE: Sectioning within the door hinge portion of the A-pillar, B-pillar or dog leg portion of the quarter panel is not approved by Ford Motor Company.

NOTE: LH side shown, RH side similar.

-

Only remove as much of the outer body side panel material as necessary using available tools.

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

-

Body side replacement panels are released as 2-part panels.

|

-

Detrim the vehicle as necessary and remove spot welds from the damaged area.

Use the General Equipment: Spot Weld Drill Bit

-

NOTE: Use resistance spotwelding equipment where possible. This will produce a higher quality repair.

NOTE: When welding overlapping surfaces or substrates, apply a high quality weld-through primer between the surfaces prior to welding.

Where possible, create a lap-joint backer plate using a portion of the old panel. This will create a stronger joint.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

-

Rough finish all sectioning joints with a fibre-based

body filler, final finish sectioning joints and plug welds with a

conventional body filler.

-

Properly seal all horizontal joints to prevent moisture

intrusion. Water and moisture migrate toward horizontal joints and

corrosion tends to occur more rapidly in these areas.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Proceed with the refinishing process using a Ford approved paint system and manufacturers recommendations.

-

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reinstall vehicle trim as necessary.

Vehicle Specific Body Construction. Description and Operation

Vehicle Specific Body Construction. Description and Operation

For recommended metal repair guidelines and recommendations, refer to the following illustrations and: For additional information, refer to: Specifications (501-25 Body Repairs - General Information, Specifications)...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Front Door Tweeter Speaker. Removal and Installation

Removal All vehicles Remove the front door trim panel. Refer to: Front Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation). Vehicles with: Harman Revel Audio System Remove the screws and the tweeter speaker through the front of the door panel. Vehicles with: AM/FM/CD/SYNC/Touchscreen Display Remove th..

Lincoln Nautilus 2018-2026 Service Manual: Key Programming Using Two Programmed Keys. General Procedures

Programming NOTE: This procedure works only if the spare key programming is enabled. NOTE: Two previously programmed keys are required to perform this procedure. All the steps must be completed within 30 seconds. NOTE: Make sure all the doors are closed prior to beginning this procedure and they remain closed until the procedure is complete. Locate the passive key backup st..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Auto Hold

- Switching the Lane Keeping System On and Off. Switching the Lane Keeping System Mode

- Opening the Liftgate

- New on site

- Most important about car

Programming the Garage Door Opener to Your Garage Door Opener Motor