Lincoln Nautilus: Side Panel Sheet Metal Repairs / Rear Door Skin Panel. Removal and Installation

Special Tool(s) /

General Equipment

| Grinder |

| Hot Air Gun |

| Knife |

| MIG/MAG Welding Equipment |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

NOTE:

LH side shown, RH side similar.

-

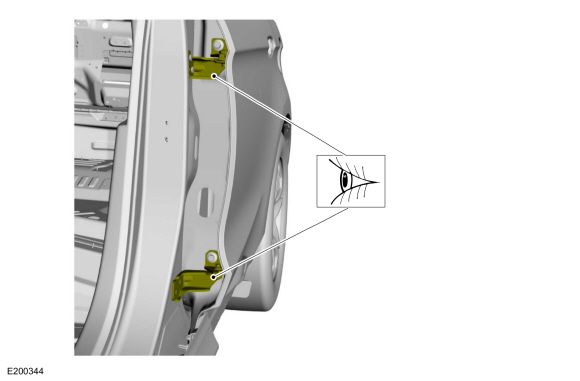

Inspect the upper and lower door hinge for wear. Rebuild or install new as necessary.

-

Remove the following items:

-

Remove the rear door window glass.

Refer to: Rear Door Window Glass (501-11 Glass, Frames and Mechanisms, Removal and Installation).

-

Remove the rear door exterior handle.

Refer to: Exterior Rear Door Handle (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

-

Remove the rear door upper moulding.

Refer to: Rear Door Upper Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

-

Remove the rear door moulding.

Refer to: Rear Door Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

-

Remove the rear door.

Refer to: Rear Door (501-03 Body Closures)

.

-

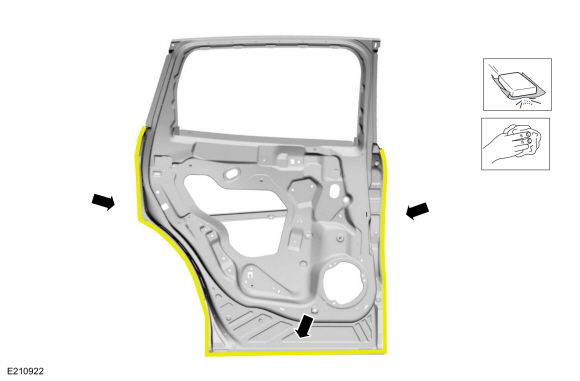

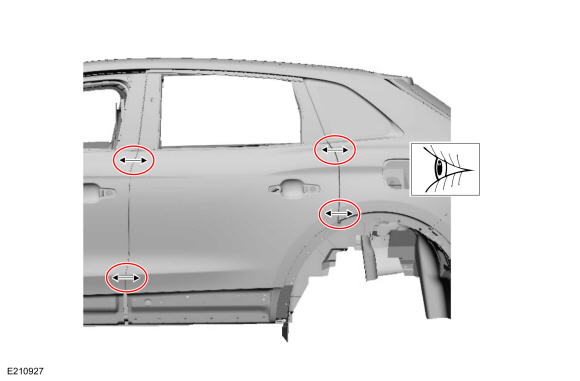

Carefully cut through the outer panel only.

Use the General Equipment: Grinder

-

Remove the outer door panel.

Use the General Equipment: Knife

Use the General Equipment: Hot Air Gun

-

Remove the remaining portion of the door skin flange.

Use the General Equipment: Knife

Use the General Equipment: Hot Air Gun

Installation

NOTE:

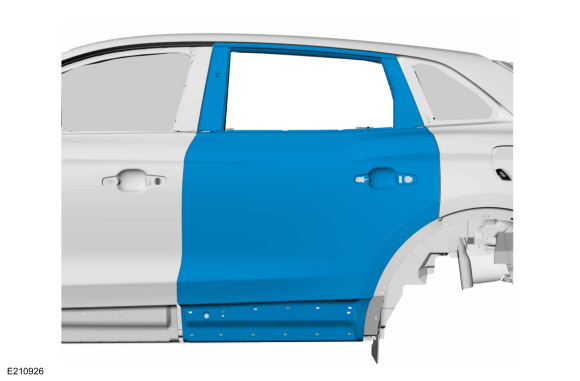

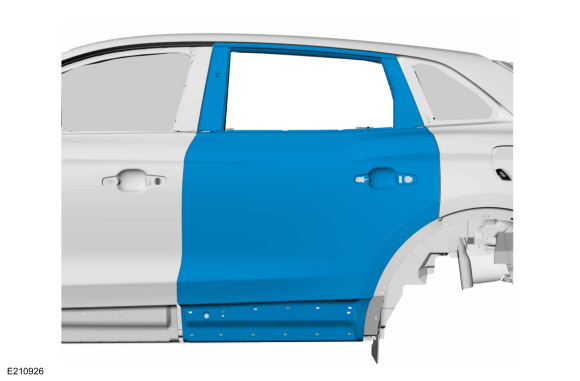

LH side shown, RH side similar.

-

Make sure the door shell is clean and free of foreign materials.

-

Remove the e-coat from the mating surface.

-

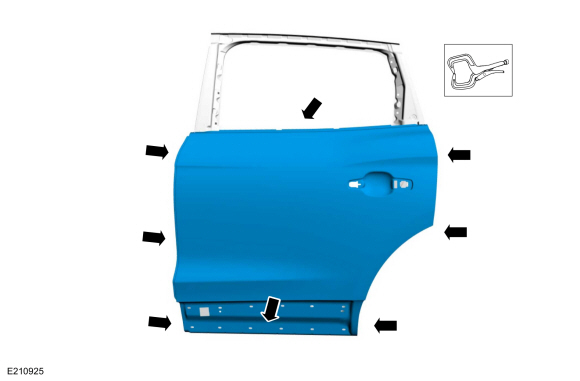

Apply adhesive to the door shell mating surfaces.

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Install and partially crimp the door skin flange.

Use the General Equipment: Locking Pliers

-

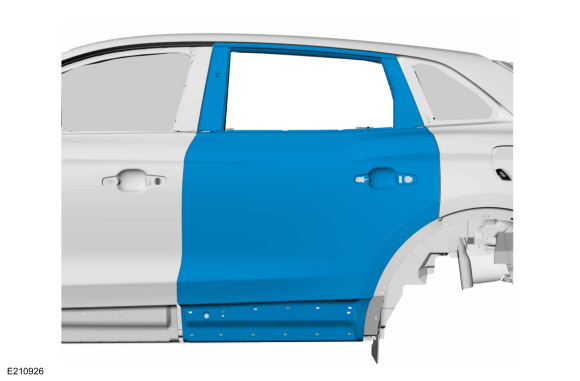

Temporarily install the door on the vehicle.

-

Check for proper alignment and adjust as necessary.

-

Carefully open the door and tack weld to lock panel in place.

Use the General Equipment: MIG/MAG Welding Equipment

-

Remove the door from the vehicle.

-

NOTE:

Smooth residual adhesive squeeze-out in to seam to act as a sealer.

Complete the hemming process.

-

Sand and clean the flange area.

-

Prime the area with a Ford approved paint system.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Apply expandable NVH foam sealant as indicated.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install NVH pad as indicated.

-

Refinish the hem area using a Ford approved paint system.

-

Refinish the door exterior using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the door.

Refer to: Rear Door (501-03 Body Closures)

.

-

Install the following items:

-

Install the rear door window glass.

Refer to: Rear Door Window Glass (501-11 Glass, Frames and Mechanisms, Removal and Installation).

-

Install the rear door exterior handle.

Refer to: Exterior Rear Door Handle (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

-

Install the rear door upper moulding.

Refer to: Rear Door Upper Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

-

Install the rear door moulding.

Refer to: Rear Door Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Hot Air Gun

Air Body Saw

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Flexible Foam Repair3M™ 08463, LORD Fusor® 121

-

Removal

R..

Other information:

Inspection

NOTE:

Depending on refrigerant used:

Use a Rotunda-approved Electronic Leak Detector for R134a refrigerant SAE Certified to J2791.

Use a Rotunda-approved Electronic Leak Detector for R-1234yf refrigerant SAE Certified to J2913.

NOTE:

Good ventilation is necessary in the area where electronic A/C

leak testing is to be carried out. If the surrounding air is

c..

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Scraper for Straight Edges

Grinder

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, ..

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Rocker Panel. Removal and Installation

Rocker Panel. Removal and Installation