Lincoln Nautilus: Roof Sheet Metal Repairs / Roof Rear Frame. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| 8 mm Drill Bit | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

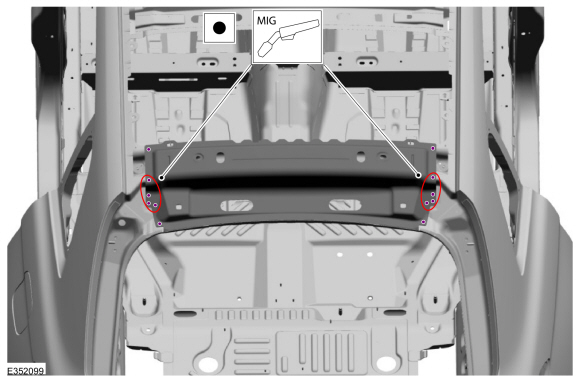

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If required:

Dimensionally restore the vehicle to pre-damaged condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

If required:

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

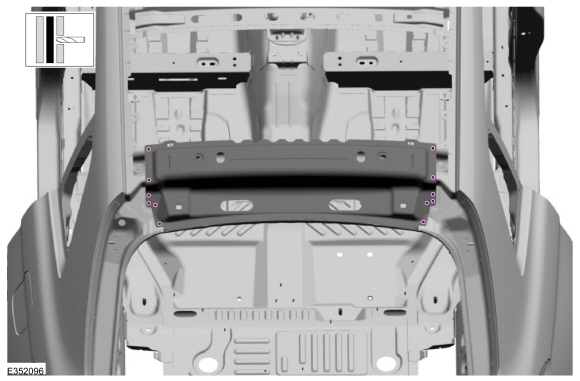

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Pay particular attention to the location of adhesives and sealers to aid in installation.

Remove the roof rear frame.

.jpg) |

Installation

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

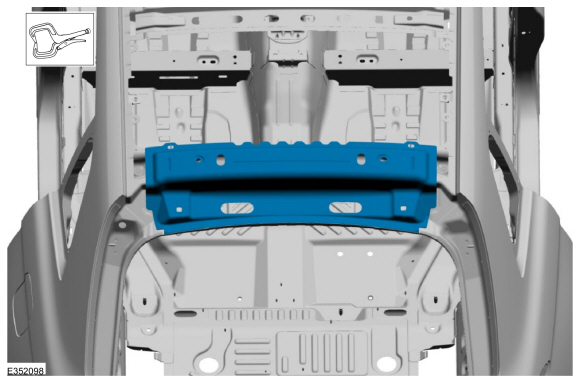

Drill plug weld holes in the replacement roof rear frame.

Use the General Equipment: 8 mm Drill Bit

|

-

Install, properly position and clamp the roof rear frame.

Use the General Equipment: Locking Pliers

|

-

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work:

All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

If required:

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Roof Reinforcement. Removal and Installation

Roof Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Evaporator Core Leak Check. General Procedures

Inspection Recover the refrigerant. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information, General Procedures). Disconnect the evaporator from the A/C system...

Lincoln Nautilus 2018-2026 Owners Manual: Launching or Retrieving a Boat or Personal Watercraft. Towing Weights and Dimensions

Launching or Retrieving a Boat or Personal Watercraft When backing down a ramp during boat launching or retrieval: Do not allow the static water level to rise above the bottom edge of the rear bumper. Do not allow waves to break higher than 6 in (15 cm) above the bottom edge of the rear bumper...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Auto Hold

- Folding the Exterior Mirrors - Vehicles With: Manual Folding Mirrors. Folding the Exterior Mirrors - Vehicles With: Power Folding Mirrors

- Replacing the Rear Wiper Blades

- New on site

- Most important about car

Opening and Closing the Hood

Opening the Hood