Lincoln Nautilus: Hydraulic Brake Actuation / Brake Master Cylinder. Removal and Installation

Removal

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTE: Removal steps in this procedure may contain installation details.

-

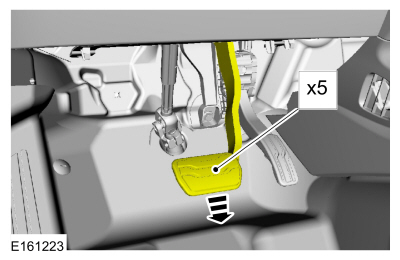

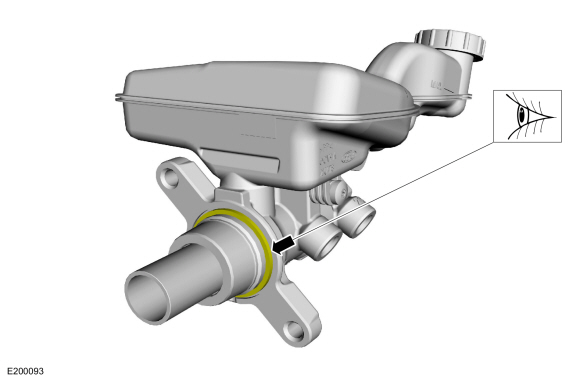

NOTICE: Before removing the master cylinder, relieve the vacuum in the brake booster or the master cylinder O-ring seal may be drawn into the brake booster, causing brake booster failure and increased brake pedal effort.

Fully apply and release the brake pedal 5 times.

|

-

Remove the battery.

Refer to: Battery (414-01 Battery, Mounting and Cables, Removal and Installation).

-

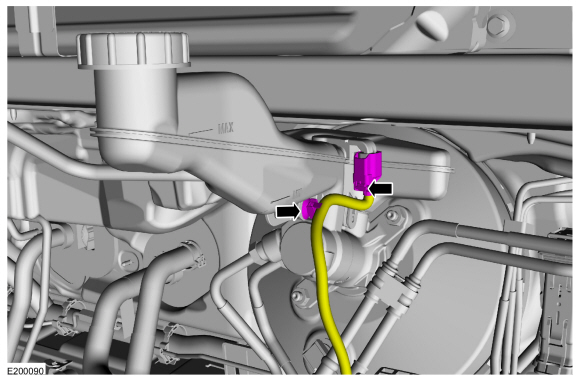

Disconnect the brake fluid level sensor electrical connector and detach the wiring retainer.

|

-

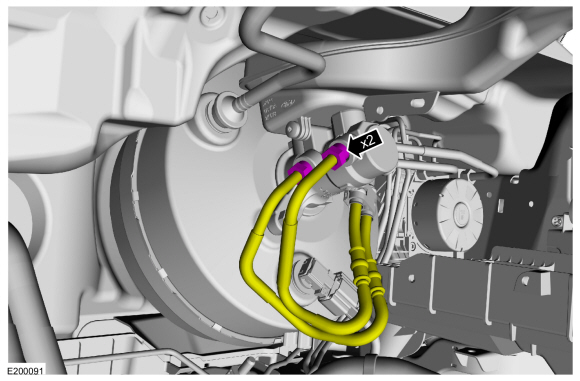

Disconnect the brake tube fittings.

Torque: 20 lb.ft (27.5 Nm)

|

-

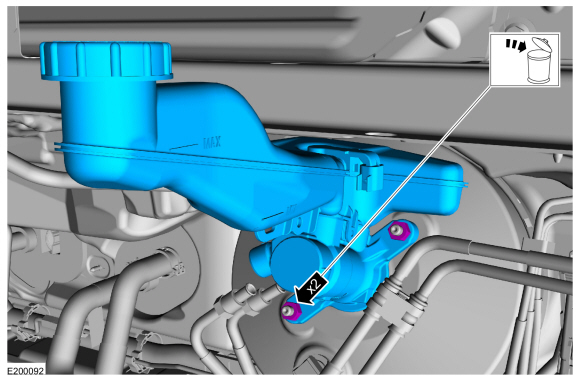

Remove the nuts and the brake master cylinder. Discard the nuts.

Torque: 20 lb.ft (27.6 Nm)

|

-

Make sure that the master cylinder-to-booster seal is removed with the master cylinder.

|

Installation

-

To install, reverse the removal procedure.

-

-

If a new brake master cylinder has been installed, bleed the master cylinder.

Refer to: Component Bleeding (206-00 Brake System - General Information, General Procedures).

-

If the brake master cylinder was removed to access other components, bleed the brake system.

Refer to: Brake System Pressure Bleeding (206-00 Brake System - General Information, General Procedures).

-

If a new brake master cylinder has been installed, bleed the master cylinder.

Brake Fluid Reservoir. Removal and Installation

Brake Fluid Reservoir. Removal and Installation

Materials

Name

Specification

Motorcraft® DOT 4 LV High Performance Motor Vehicle Brake FluidPM-20

WSS-M6C65-A2

Removal

NOTICE:

Do not spill brake fluid on painted or plastic surfaces or

damage to the surface may occur...

Brake Pedal and Bracket. Removal and Installation

Brake Pedal and Bracket. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the nuts, disconnect the electrical connector and remove the LH insulator panel...

Other information:

Lincoln Nautilus 2018-2026 Owners Manual: Automatic Locking Mode

What Is Automatic Locking Mode This is a safety feature built into the seatbelt retractors that keeps the seatbelts pre-locked. Engaging Automatic Locking Mode Fasten the combination lap and shoulder belt. Grasp the shoulder portion and pull downward until you pull the entire belt out...

Lincoln Nautilus 2018-2026 Service Manual: Roof Panel. Removal and Installation

Special Tool(s) / General Equipment Resistance Spotwelding Equipment Scraper for Straight Edges Spherical Cutter Hot Air Gun Spot Weld Drill Bit Locking Pliers Materials Name Specification Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 - Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM - ..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Drive Mode Control

- Interior Lamp Function. Adjusting the Instrument Panel Lighting Brightness. Ambient Lighting. Interior Lighting – Troubleshooting

- Normal Scheduled Maintenance

- New on site

- Most important about car

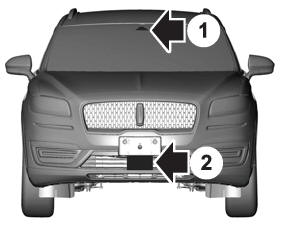

Locating the Pre-Collision Assist Sensors

If a message regarding a blocked sensor or camera appears in the information display, something is obstructing the radar signals or camera images. The radar sensor is behind the fascia cover in the center of the lower grille. With a blocked sensor or camera, the system may not function, or performance may reduce. See Pre-Collision Assist – Information Messages.