Lincoln Nautilus: Engine System - General Information / Crankshaft Main Bearing Journal Clearance. General Procedures

Lincoln Nautilus 2018-2026 Service Manual / Powertrain / Engine / Engine System - General Information / Crankshaft Main Bearing Journal Clearance. General Procedures

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Crankshaft main bearing journals must be within specifications before checking journal clearance.

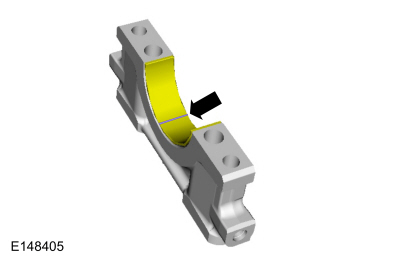

Remove the crankshaft main bearing cap and crankshaft main bearing.

-

Position a piece of Plastigage across the crankshaft main bearing surface.

|

-

NOTE: Do not turn the crankshaft while carrying out this procedure.

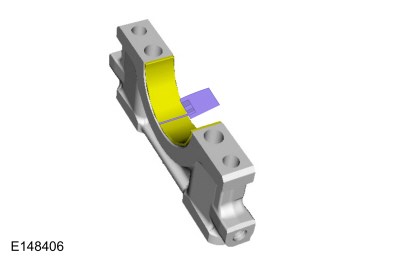

Install and tighten to specifications, then remove the crankshaft main bearing cap.

-

Measure the Plastigage to get the crankshaft main

bearing clearance. The Plastigage should be smooth and flat. A changing

width indicates a tapered or damaged crankshaft or crankshaft bearing.

|

Crankshaft End Play. General Procedures

Crankshaft End Play. General Procedures

General Equipment

Dial indicator

Dial indicator fixture

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Position the crankshaft to the rear of the cylinder block...

Cylinder Block Core Plug Replacement. General Procedures

Cylinder Block Core Plug Replacement. General Procedures

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock 262TA-26

WSK-M2G351-A6

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Cylinder Block Distortion. General Procedures

Special Tool(s) / General Equipment Feeler Gauge Check NOTE: Refer to the appropriate Section 303-01 for the specification. NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent...

Lincoln Nautilus 2018-2026 Service Manual: Vehicle Dynamic Suspension - Component Location. Description and Operation

Item Description 1 VDM 2 Rear height sensor (2 required) 3 Front height sensor (2 required) 4 Strut with solenoid (2 required) 5 Shock with solenoid (2 required) ..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Interior Lamp Function. Adjusting the Instrument Panel Lighting Brightness. Ambient Lighting. Interior Lighting – Troubleshooting

- Opening the Liftgate

- Anti-Theft Alarm System Settings. Security – Troubleshooting

- New on site

- Most important about car

Parking Aid Indicators. Parking Aids – Troubleshooting

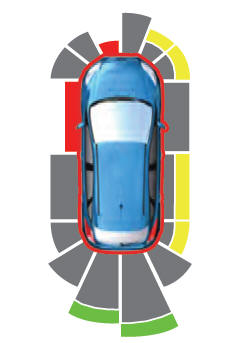

Parking Aid Indicators

The system provides object distance indication through the information and entertainment display.

As the distance to the object decreases, the indicator waves and the lines move toward the vehicle icon. If there is no object detected, the distance indicator lines are grey.Copyright © 2026 www.linautilus.com