Lincoln Nautilus: Glass, Frames and Mechanisms / Fixed Glass. General Procedures

Special Tool(s) / General Equipment

| Glass Cut-Out Wire | |

| Power Caulk Gun | |

| Power Fixed Glass Removal Tool | |

| Cold Knife | |

| Knife | |

| Vacuum Cleaner |

Materials

| Name | Specification |

|---|---|

| Sika® SikaTack® MACH 60 / Sika® SikaTack® MACH 30 / Dow® BETASEAL™ Express | - |

| Sika Tack ASAP Urethane Adhesive | - |

| Motorcraft® Ultra-Clear Spray Glass Cleaner ZC-23 |

ESR-M14P5-A |

| Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207 | - |

Repair

-

NOTE: Some interior trim, exterior trim and/or components may require removal based on the tools and removal method used.

NOTE: In some instances repair methods may be combined to achieve the best results.

NOTE: If any of the following conditions exist, the fixed glass must be discarded. A new fixed glass is required.

- The fixed glass is the windshield glass and equipped with a camera bracket.

- The fixed glass is the windshield glass and equipped with adhesive mouldings.

-

Cold knife method – uses the cold knife to cut the

urethane from the outside of a vehicle provided the blade can reach the

bead.

Use the General Equipment: Cold Knife

-

Power tool method – uses various power tools from inside the vehicle using a cutting or paddle type blade.

Use the General Equipment: Power Fixed Glass Removal Tool

-

Piano wire method – uses the piano wire to cut the

urethane from inside and outside of a vehicle using an assistant.

Use the General Equipment: Glass Cut-Out Wire

-

When using the cold knife method, apply tape to protect

the perimeter of the window opening from paint damage. Multiple layers

of tape may be required.

-

NOTICE: New or reused fixed glass must be installed within 2 hours of cutting the urethane adhesive. Exposed cut surfaces of urethane become oxidized and inactive beyond 2 hours, reducing the effectiveness of the repair bond.

NOTICE: To avoid rust formation, use extreme care not to scratch the paint or primer or damage the pinch weld during glass removal.

NOTICE: Take precautions to prevent damage to other components when cutting urethane.

NOTE: If any of the following conditions exist, the fixed glass must be discarded. A new fixed glass is required.

- The fixed glass is the windshield glass and equipped with a camera bracket.

- The fixed glass is the windshield glass and equipped with adhesive mouldings.

NOTE: Fixed glass may have locating pins that vary in location. It may be necessary to cut these pins with a utility knife.

Remove the fixed glass.

Use the General Equipment: Power Fixed Glass Removal Tool

Use the General Equipment: Cold Knife

Use the General Equipment: Knife

-

WARNING:

Repair any corrosion found on the pinch weld. The

pinch weld is a structural component of the vehicle. Corrosion left

unrepaired may reduce the structural integrity of the vehicle. Failure

to follow this instruction may result in serious injury to vehicle

occupant(s).

WARNING:

Repair any corrosion found on the pinch weld. The

pinch weld is a structural component of the vehicle. Corrosion left

unrepaired may reduce the structural integrity of the vehicle. Failure

to follow this instruction may result in serious injury to vehicle

occupant(s).

NOTICE: New or reused fixed glass must be installed within 2 hours of cutting the urethane adhesive. Exposed cut surfaces of urethane become oxidized and inactive beyond 2 hours, reducing the effectiveness of the repair bond.

NOTE: Avoid scratching the pinch weld. Repair all minor scratches or exposed metal on the pinch weld following manufacturer's instructions for the product being used. Use the same brand primer and urethane adhesive.

NOTE: Touching the adhesive surface impairs the rebonding.

NOTE: Make sure the mating surfaces are clean and free of foreign material.

NOTE: If replacing the windshield glass and equipped with a camera bracket, it must have locating pins and spacers to ensure correct alignment. Do not use a replacement windshield glass, without locating pins and spacers.

Prep the pinch weld area to install the new or reused fixed glass.

-

Trim or shave down the original urethane adhesive on

pinch weld flange and on glass (if reused) using a utility knife,

leaving a 1 mm to 2 mm (0.04 in to 0.08 in) base on the parts, only when

final installation is within 2 hours.

-

Remove any foreign material or dirt from the pinch weld using a soft brush or vacuum.

Use the General Equipment: Vacuum Cleaner

-

Trim or shave down the original urethane adhesive on

pinch weld flange and on glass (if reused) using a utility knife,

leaving a 1 mm to 2 mm (0.04 in to 0.08 in) base on the parts, only when

final installation is within 2 hours.

-

NOTE: Minimize applying primer over areas with remaining urethane adhesive and observe a minimum flash time of 10 minutes.

If the paint layer was damaged on the pinch weld extending into bare metal, apply primer to those areas only.

Material: Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207

-

NOTE: Minimize applying primer over areas with remaining urethane adhesive and observe a minimum flash time of 10 minutes.

Apply primer as necessary.

-

Apply primer to those areas only previously primed with primer.

Material: Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207

-

If the clearcoat layer was damaged on the pinch weld

but not extending into bare metal, apply primer to those areas only.

Material: Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207

-

Apply primer to those areas only previously primed with primer.

-

NOTE: This step only applies when installing a new fixed glass.

Clean the inside of the new fixed glass with glass cleaner.

Material: Motorcraft® Ultra-Clear Spray Glass Cleaner / ZC-23 (ESR-M14P5-A)

-

NOTE: This step only applies when installing a new fixed glass.

Apply primer according to the manufacturer's instructions to the new fixed glass. Allow at least 10 minutes to dry.

Material: Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207

-

NOTE: This step only applies to reusable fixed glass.

Visually inspect and remove remaining urethane adhesive from the glass leaving a thin layer to bond with the new urethane adhesive bead.

-

NOTE: This step only applies to reusable fixed glass.

Apply primer according to the manufacturer's instructions to the fixed glass anywhere the urethane adhesive was completely removed. Allow at least 10 minutes to dry.

Material: Sika® Aktivator PRO / Dow® BETAPRIME™ 5504G / Sika® Primer-207

-

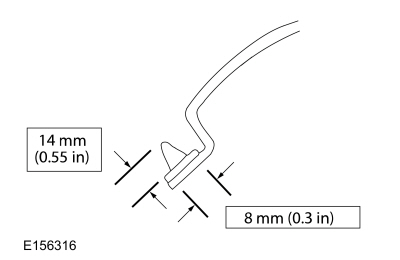

Cut the urethane adhesive applicator tip to specification.

Material: Sika® SikaTack® MACH 60 / Sika® SikaTack® MACH 30 / Dow® BETASEAL™ Express

Material: Sika Tack ASAP Urethane Adhesive

.jpg) |

-

NOTICE: Make sure the urethane bead is uniform to prevent air and water leaks.

NOTE: The fixed glass must be installed within 10 minutes of applying the urethane adhesive.

NOTE: Use a power caulk gun that applies the urethane adhesive with less effort and a continuous bead.

Apply a urethane adhesive bead.

-

Start and end at the original overlap points to prevent air and water leaks.

-

NOTE: Take care in applying urethane on vehicles without peripheral moldings as urethane expulsion could become an appearance issue.

Apply a urethane adhesive bead 14 mm (0.551 in) high and 8 mm (0.314 in) wide on top of the existing trimmed urethane adhesive bead on the pinch weld.

Use the General Equipment: Power Caulk Gun

Material: Sika® SikaTack® MACH 60 / Sika® SikaTack® MACH 30 / Dow® BETASEAL™ Express

Material: Sika Tack ASAP Urethane Adhesive

-

Make sure there are no gaps in the bead.

-

Start and end at the original overlap points to prevent air and water leaks.

|

-

NOTICE: The door windows must be left open during the adhesive curing time.

Open the vehicle windows to prevent the air pressure of closing doors from compromising the urethane adhesive bond.

-

WARNING:

Improper curing of the urethane adhesive may

adversely affect glass retention, which is important for restraint

system performance during a crash. Carefully follow the urethane

adhesive manufacturer's curing instructions. Do not drive the vehicle

until the urethane adhesive seal has cured. Failure to follow these

instructions may result in serious injury to vehicle occupant(s) during a

crash.

WARNING:

Improper curing of the urethane adhesive may

adversely affect glass retention, which is important for restraint

system performance during a crash. Carefully follow the urethane

adhesive manufacturer's curing instructions. Do not drive the vehicle

until the urethane adhesive seal has cured. Failure to follow these

instructions may result in serious injury to vehicle occupant(s) during a

crash.

NOTE: If equipped, the adhesive strip backings must be removed from the A-pillar mouldings before installing the fixed glass.

NOTE: If replacing the windshield glass and equipped with a camera bracket, it must have locating pins and spacers to ensure correct alignment. Do not use a replacement windshield glass, without locating pins and spacers.

Install the fixed glass to the vehicle.

-

Install the fixed glass, pressing firmly by hand to ensure a good bond.

-

Secure the fixed glass in the correct position with tape until the urethane adhesive has cured.

-

Install the fixed glass, pressing firmly by hand to ensure a good bond.

-

If necessary, remove excess uncured urethane adhesive from the interior and exterior surface of the fixed glass.

Material: Motorcraft® Ultra-Clear Spray Glass Cleaner / ZC-23 (ESR-M14P5-A)

-

Install any removed components as needed.

-

If equipped, carry out the IPMA camera alignment.

Refer to: Lane Keeping System - System Operation and Component Description (419-07 Lane Keeping System, Description and Operation).

Glass, Frames and Mechanisms. Diagnosis and Testing

Glass, Frames and Mechanisms. Diagnosis and Testing

DTC Chart: HVAC Module

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Heated Window Grid Wire Repair. General Procedures

Heated Window Grid Wire Repair. General Procedures

Materials

Name

Specification

Motorcraft® Ultra-Clear Spray Glass CleanerZC-23

ESR-M14P5-A

Motorcraft® Rear Window Defroster RepairPM-11

WSB-M4J58-B

Motorcraft® Lacquer Touch-Up PaintPMPC-19500-XXXXA, PMPM-19500-XXXXG, PMPP-19500-XXXXA

ESR-M2P100-C

Repair

NOTE:

The antenna and heated window grid line material is not

embedded into the glass..

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Piston Ring End Gap. General Procedures

Special Tool(s) / General Equipment Feeler Gauge Check NOTE: Refer to the appropriate Section 303-01 for the specification. NOTE: Use care when fitting piston rings to avoid possible damage to the piston ring or the cylinder bore. NOTE: Piston rings should not be transferred from one piston to another. NOTE: The cylinder bore must be within specification for ta..

Lincoln Nautilus 2018-2026 Service Manual: Headlamp Adjustment. General Procedures

Adjustment NOTE: If the flash video link does not load or is incompatible with your browser, a .wmv version of the video can be accessed at: http://www.fordservicecontent.com/Ford_Content/videos/FusionHeadlampAdj2.wmv Click on the link above to view video. Click here to view a video version of this procedure. All headlamp types NOTE: Refer to the Owner's..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Engine Oil Capacity and Specification - 2.0L

- Opening the Liftgate

- Power Outlet - Vehicles With: 110V Power Outlet

- New on site

- Most important about car

Clearing the Garage Door Opener. Reprogramming the Garage Door Opener. Garage Door Opener Radio Frequencies

Clearing the Garage Door Opener