Lincoln Nautilus: Front End Sheet Metal Repairs / Front Side Member and Fender Apron Panel LH. Removal and Installation

Special Tool(s) /

General Equipment

| Air Body Saw |

| 8 mm Drill Bit |

| MIG/MAG Welding Equipment |

| Spot Weld Drill Bit |

| Locking Pliers |

Materials

| Name |

Specification |

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Removal

NOTE:

Left hand (LH) side shown, right hand (RH) side similar.

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds. Resistance welds may not be placed directly

over original location. They must be placed adjacent to original

location and match factory welds in quantity. Metal inert gas (MIG) plug

welds must equal factory welds in both location and quantity.

NOTE:

Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the fender apron panel reinforcement.

Refer to: Fender Apron Panel Reinforcement (501-27 Front End Sheet Metal Repairs, Removal and Installation).

-

Remove the engine.

Refer to: Engine (303-01A Engine - 2.0L EcoBoost (184kW/250PS) – MI4, Removal).

Refer to: Engine (303-01B Engine - 2.7L EcoBoost (238kW/324PS), Removal).

-

Remove the radiator.

Refer to: Radiator (303-03A Engine Cooling - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation).

Refer to: Radiator (303-03B Engine Cooling - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Remove the front impact severity sensor.

Refer to: Front Impact Severity Sensor (501-20B Supplemental Restraint System, Removal and Installation).

-

On both side.

Remove the front seat.

Refer to: Front Seat (501-10A Front Seats, Removal and Installation).

-

Remove the instrument panel.

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

-

Remove the restraints control module.

Refer to: Restraints Control Module (RCM) (501-20B Supplemental Restraint System, Removal and Installation).

-

Position the carpet and wiring harness away from the working area.

-

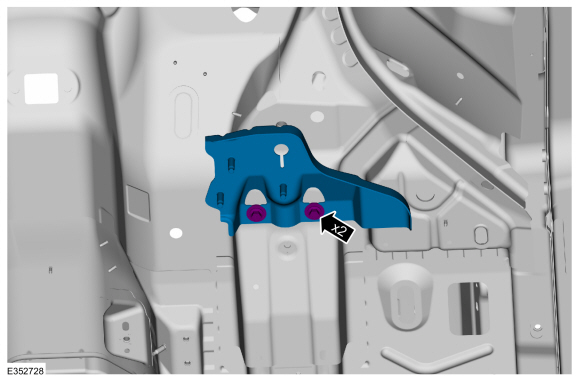

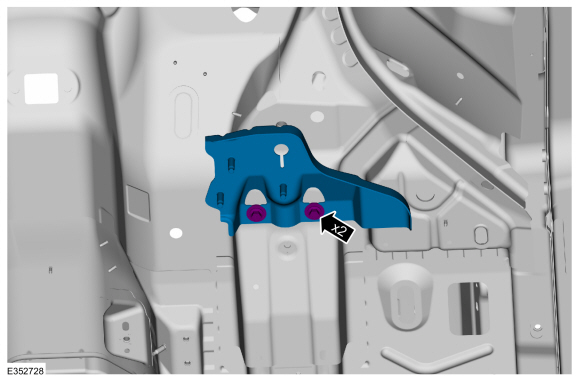

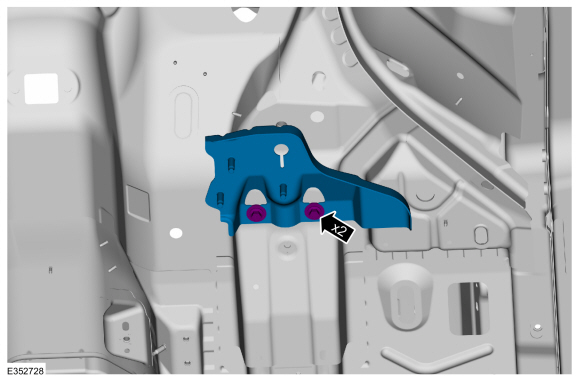

Remove the retainers and the front crossmember support mounting bracket.

-

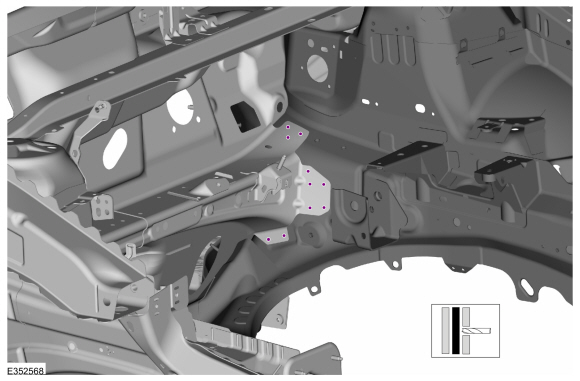

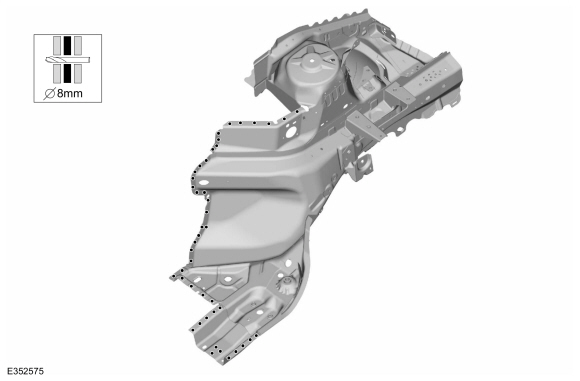

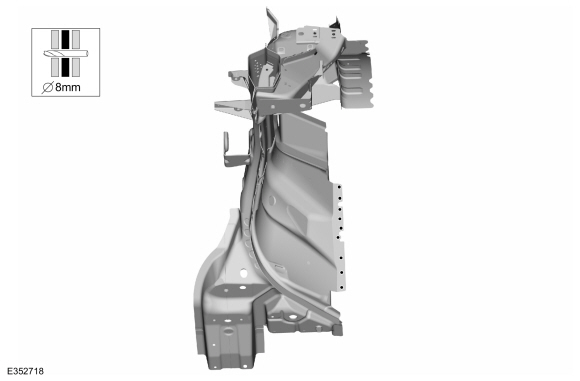

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

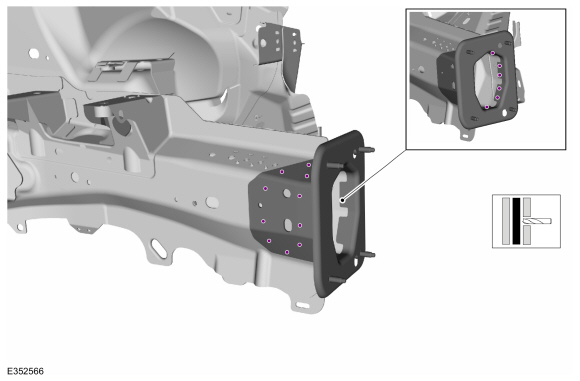

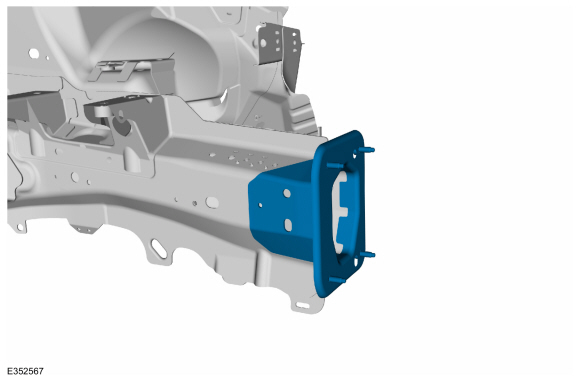

Remove the bumper bracket.

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

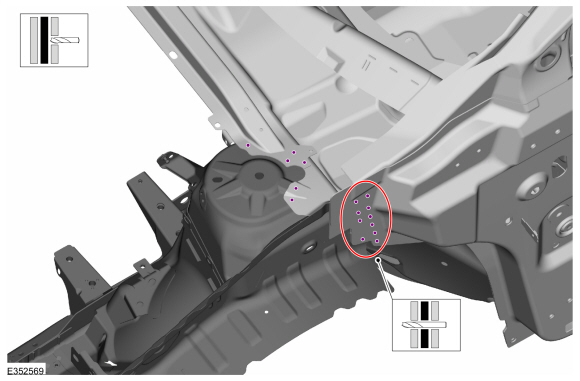

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

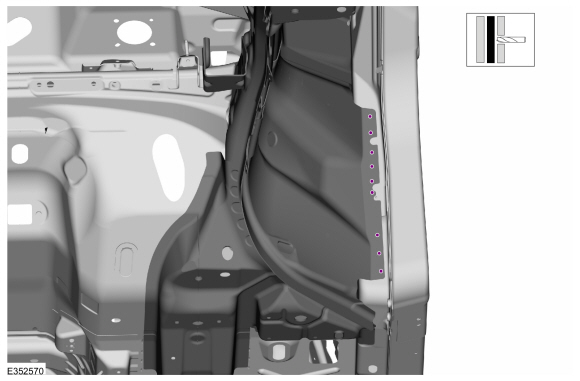

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

-

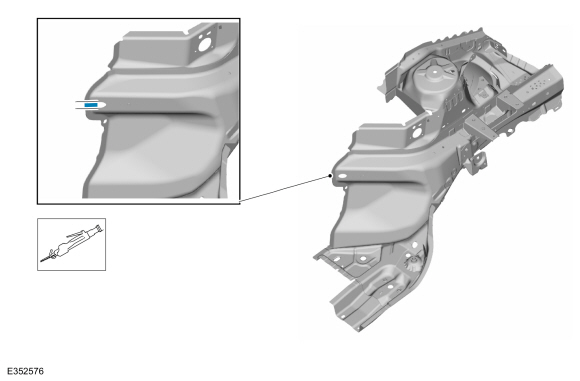

NOTE:

A partial section needs to be cut out at the apron panel to remove side member with the apron panel.

Carefully cut the partial section from the apron panel.

Use the General Equipment: Air Body Saw

-

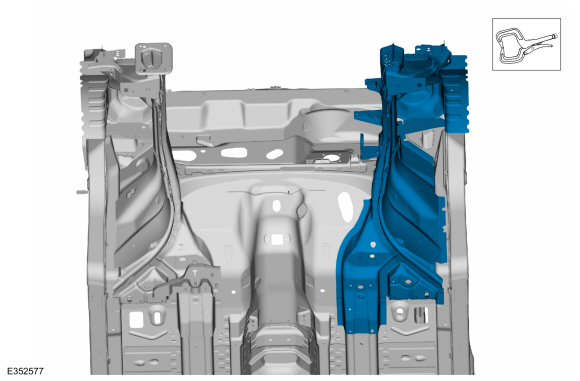

Remove the front side member and fender apron panel.

Installation

NOTE:

Left hand (LH) side shown, right hand (RH) side similar.

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds. Resistance welds may not be placed directly

over original location. They must be placed adjacent to original

location and match factory welds in quantity. Metal inert gas (MIG) plug

welds must equal factory welds in both location and quantity.

NOTE:

Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

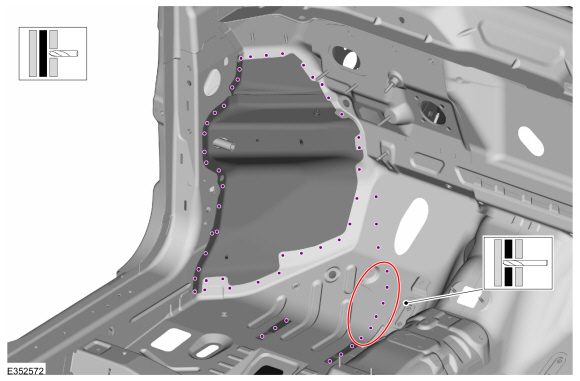

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

-

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

-

NOTE:

A partial section needs to be cut out at the apron panel to enable installation of the side member.

Carefully cut the partial section from the apron panel.

Use the General Equipment: Air Body Saw

-

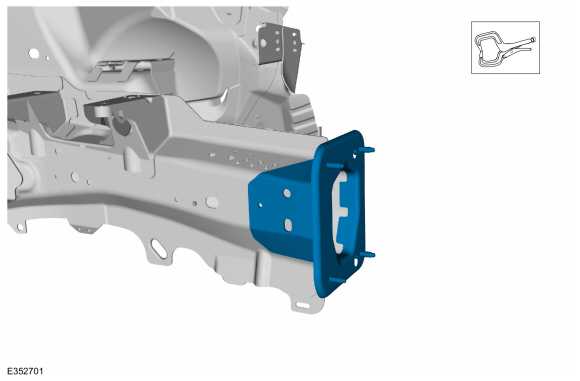

Install,properly position and clamp the front side member and fender apron panel.

Use the General Equipment: Locking Pliers

-

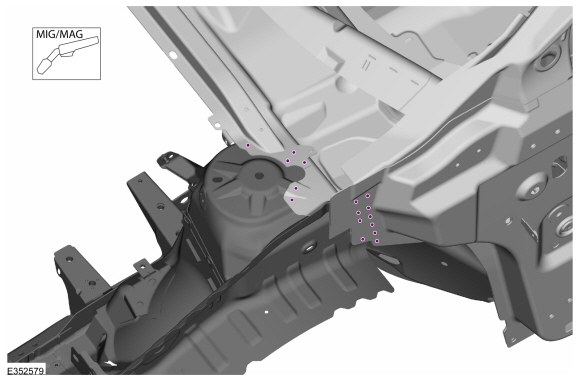

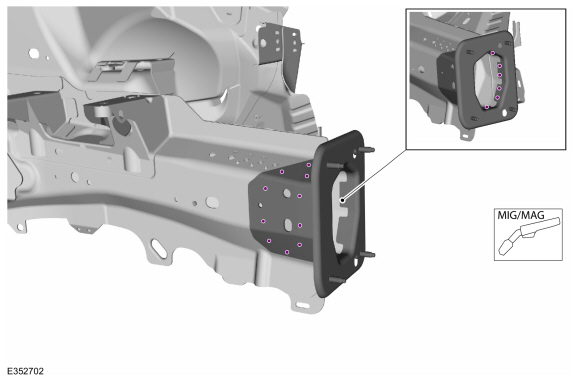

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

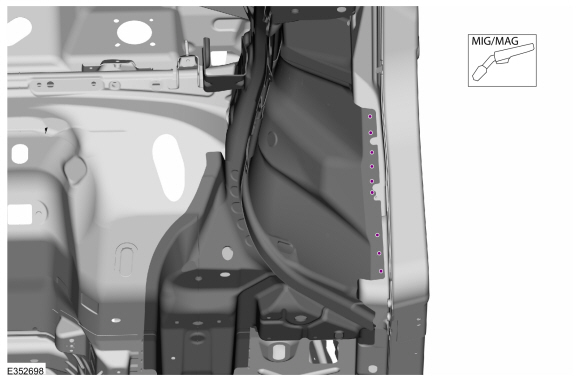

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

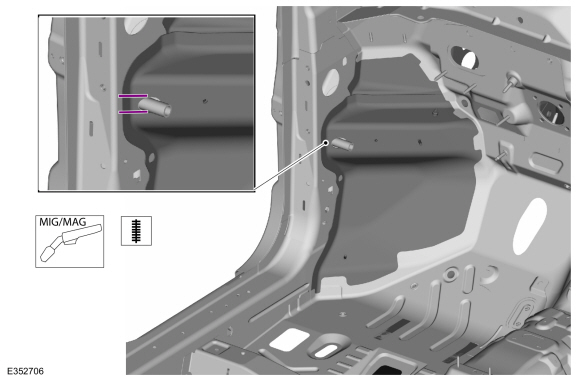

Install the seam weld as indicated.

Use the General Equipment: MIG/MAG Welding Equipment

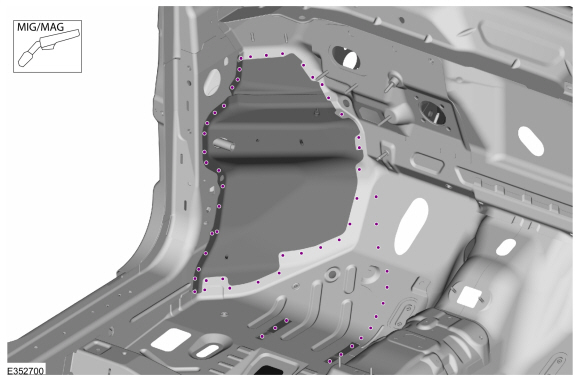

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Install,properly position and clamp the bumper bracket.

Use the General Equipment: Locking Pliers

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reosition the carpeting and wiring harness to original location.

-

Position the front crossmember support mounting bracket and install the retainers.

Torque:

35 lb.ft (48 Nm)

|

|

-

Install the following items:

-

Install the restraints control module.

Refer to: Restraints Control Module (RCM) (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the instrument panel.

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

-

On both side.

Install the front seat.

Refer to: Front Seat (501-10A Front Seats, Removal and Installation).

-

Install the front impact severity sensor.

Refer to: Front Impact Severity Sensor (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the radiator.

Refer to: Radiator (303-03A Engine Cooling - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation).

Refer to: Radiator (303-03B Engine Cooling - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Install the engine.

Refer to: Engine (303-01A Engine - 2.0L EcoBoost (184kW/250PS) – MI4, Installation).

Refer to: Engine (303-01B Engine - 2.7L EcoBoost (238kW/324PS), Installation).

-

Install the fender apron panel reinforcement.

Refer to: Fender Apron Panel Reinforcement (501-27 Front End Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Grinder

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

Restore the vehicle to pre-accident dimensions, if required...

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Air Body Saw

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

This procedure is intended for sectioning a small portion of t..

Other information:

Checking the Tire Pressures

Safe operation of your vehicle requires

that your tires are properly inflated.

Remember that a tire can lose up to half

of its air pressure without appearing flat.

Every day before you drive, check your

tires. If one looks lower than the others,

use a tire gauge to check the pressure

of all tires and adjust if required.

At least once a month and before long

trip..

How Do Personal Profiles Work

This feature allows you to create multiple

personal profiles enabling users to

personalize vehicle’s settings such as seats

and mirrors, as well as non-positional settings

like radio, navigation, driver assist system

settings. Positional settings are saved by

holding a memory seat button.

Non-positional settings are saved you

change a setting while a profile..

Categories

WARNING: If the tire pressure

monitor sensor becomes damaged it may

not function.

Note: The use of tire sealant may damage

your tire pressure monitoring system and

should only be used in roadside

emergencies. If you must use a sealant, use

the Tire Mobility Kit sealant. Replace the tire

pressure monitoring system sensor and

valve stem on the wheel by an authorized

dealer after use of the sealant.

Note: The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply

the brake hea

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Fender Apron Panel Reinforcement. Removal and Installation

Fender Apron Panel Reinforcement. Removal and Installation Front Side Member Section. Removal and Installation

Front Side Member Section. Removal and Installation