Lincoln Nautilus: Battery, Mounting and Cables / Generator Current Sensor. Removal and Installation

Lincoln Nautilus 2018-2026 Service Manual / Electrical / Battery and Charging System / Battery, Mounting and Cables / Generator Current Sensor. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

-

Disconnect the battery cable from the negative battery post.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

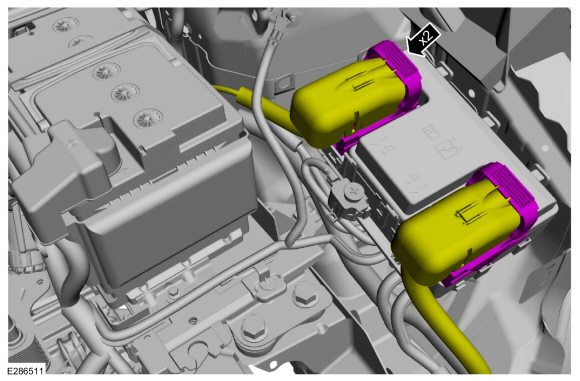

Disconnect the electrical connectors from the BJB .

|

-

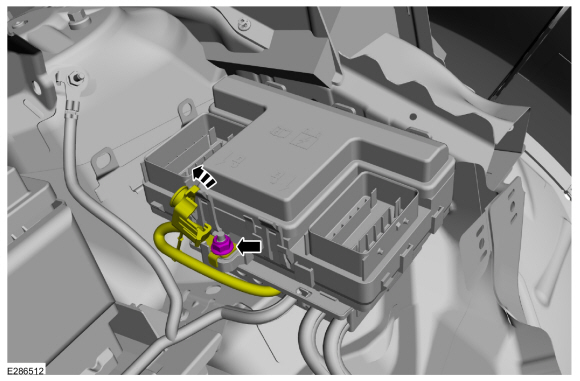

Position the terminal cover aside, remove the nut and position the wire aside from the BJB .

Torque: 177 lb.in (20 Nm)

|

-

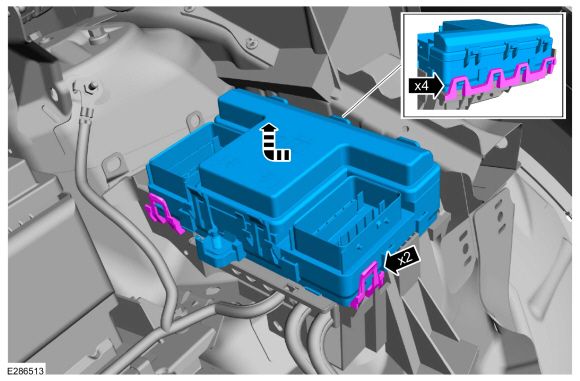

Release the front and side retainers and remove the BJB .

|

-

Release the retainers and remove the high current BJB cover.

|

-

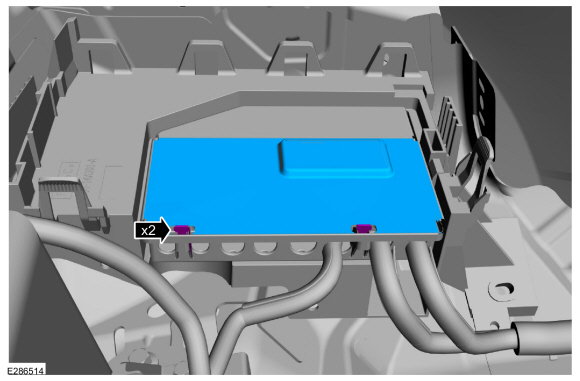

Remove the nut and the wire from the high current BJB . Detach the retainer and position the wire harness aside.

Torque: 106 lb.in (12 Nm)

|

-

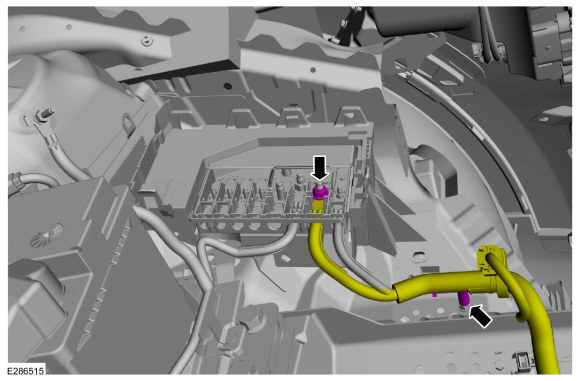

NOTE: The generator current sensor must be installed in the proper position and orientation to function correctly. Note the orientation and position of the generator current sensor tape tab.

Disconnect the generator current sensor electrical connector. Index-mark the battery cable at the generator current sensor. Remove and discard the tape securing the generator current sensor to the battery cable and remove the generator current sensor.

.jpg) |

Installation

-

To install, reverse the removal procedure.

Battery Tray. Removal and Installation

Battery Tray. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the air cleaner.

Refer to: Air Cleaner (303-12A Intake Air Distribution and Filtering -

2...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Passenger Airbag. Removal and Installation

Removal WARNING: The following procedure prescribes critical repair steps required for correct supplemental restraint system operation during a crash. Follow all notes and steps carefully. Failure to follow step instructions may result in incorrect operation of the supplemental restraint system and increases the risk of serious personal injury or death in a crash. ..

Lincoln Nautilus 2018-2026 Service Manual: Rear Door Latch. Removal and Installation

Removal NOTE: LH side shown, RH side similar. NOTE: Removal steps in this procedure may contain installation details. Remove the exterior rear door handle. Refer to: Exterior Rear Door Handle (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation). NOTE: The rear door removed for clarity. Remove the exterior door handle reinforcement sc..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Opening and Closing the Hood

- Massage Seats

- Interior Lamp Function. Adjusting the Instrument Panel Lighting Brightness. Ambient Lighting. Interior Lighting – Troubleshooting

- New on site

- Most important about car

Parking Aid Indicators. Parking Aids – Troubleshooting

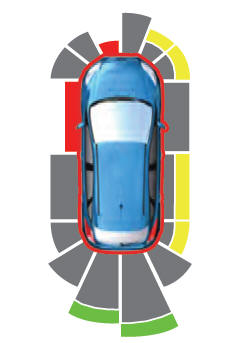

Parking Aid Indicators

The system provides object distance indication through the information and entertainment display.

As the distance to the object decreases, the indicator waves and the lines move toward the vehicle icon. If there is no object detected, the distance indicator lines are grey.Copyright © 2026 www.linautilus.com