Lincoln Nautilus: Parking Brake and Actuation / Parking Brake Actuator Motor. Removal and Installation

Lincoln Nautilus 2018-2026 Service Manual / Chassis / Brake System / Parking Brake and Actuation / Parking Brake Actuator Motor. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

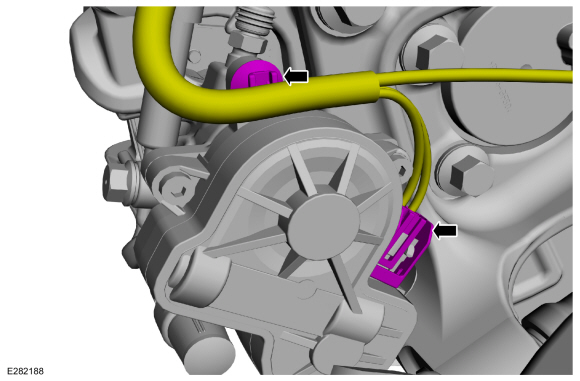

Disconnect the electrical connector and detach the wiring retainer.

|

-

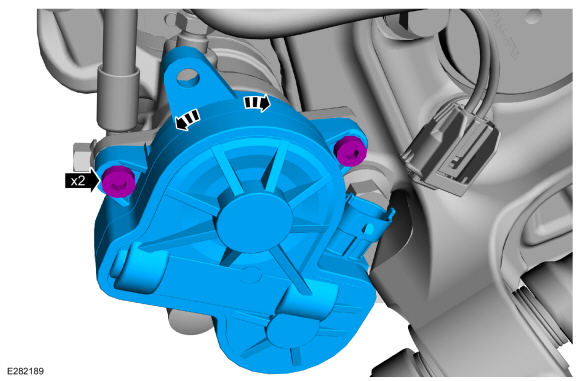

NOTE: Once the actuator motor is removed, if there is evidence of brake fluid found in or around the parking brake actuator motor a new brake caliper and actuator motor assembly must be installed.

Remove the bolts and using a twisting motion, remove the parking brake actuator motor.

Torque: 71 lb.in (8 Nm)

|

-

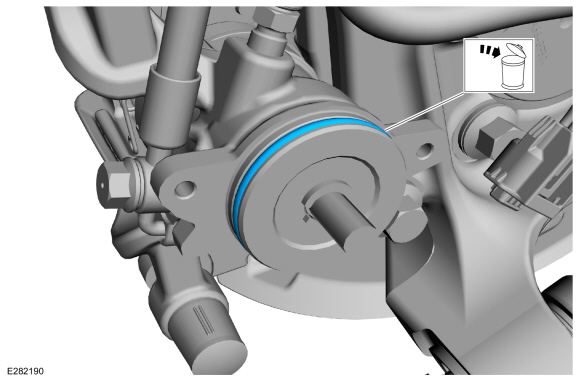

Remove and discard the O-ring.

|

-

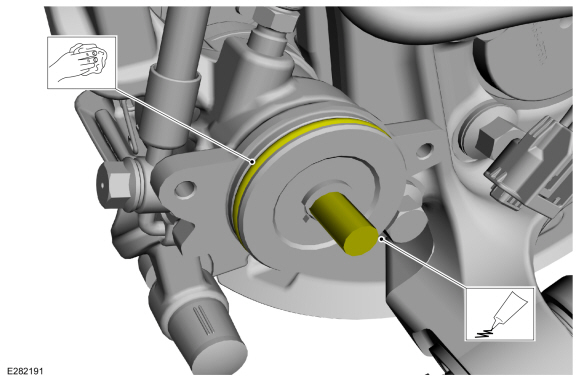

Clean the brake caliper housing O-ring groove and apply the grease supplied with the parking kit.

|

Installation

-

NOTE: Use the grease and new bolts supplied with the parking brake actuator motor kit.

To install, reverse the removal procedure.

Electronic Parking Brake (EPB) Service Mode Activation and Deactivation. General Procedures

Electronic Parking Brake (EPB) Service Mode Activation and Deactivation. General Procedures

Activation

WARNING:

Service actions on vehicles equipped with electronic parking

brakes may cause unexpected parking brake application, which could

result in injury to hands or fingers...

Parking Brake Switch. Removal and Installation

Parking Brake Switch. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Detach the clips and pivot the instrument panel LH lower trim panel downward...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Tire Pressure Monitoring System (TPMS) Sensor Activation. General Procedures

Special Tool(s) / General Equipment 204-D081A (204-D081) Tire Pressure Monitor (TPMS) Activation NOTE: The tire pressure sensors will go into a "sleep mode" when a vehicle is stationary to conserve battery power. The sensors do not transmit information while in sleep mode...

Lincoln Nautilus 2018-2026 Service Manual: Air Conditioning (A/C) Clutch and Air Conditioning (A/C) Clutch Field Coil. General Procedures

Special Tool(s) / General Equipment 412-001 (T71P-19703-B) Remover, Compressor Pulley Activation Remove the A/C compressor. Refer to Air Conditioning A/C Compressor procedure in Group 412. NOTE: If equipped with spring rubber clutch...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Anti-Theft Alarm System Settings. Security – Troubleshooting

- USB Ports

- Power Outlet - Vehicles With: 110V Power Outlet

- New on site

- Most important about car

Replacing the Rear Wiper Blades

Note: Do not hold the wiper blade to lift the wiper arm.

Remove the wiper blade.Copyright © 2026 www.linautilus.com