Lincoln Nautilus: Supplemental Restraint System / Pyrotechnic Device Disposal. General Procedures

Disposal

Disposal of Deployable Devices and Pyrotechnic Devices That Are Undeployed-Inoperative

NOTE: All inoperative airbags, seatbelt pretensioners and inflatable seatbelt inflators have been placed on the Mandatory Return List. Treat all discolored or damaged airbags the same as any inoperative live airbag being returned.

-

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

WARNING:

Before beginning any service procedure in this

manual, refer to health and safety warnings in section 100-00 General

Information. Failure to follow this instruction may result in serious

personal injury.

-

Depower the SRS

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the undeployed/inoperative device. Refer to

the appropriate procedure in this section or in the seatbelt system

section.

-

NOTE: When installing a new airbag or inflatable seatbelt inflator, a prepaid return postcard is provided with the replacement part. The serial number for the new part and the VIN must be recorded and sent to Ford Motor Company.

If installing a new airbag, or inflatable seatbelt inflator, record the necessary information and return the inoperative airbag to Ford Motor Company.

Disposal of Deployable Devices and Pyrotechnic Devices That Are Deployed

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the deployed device. Refer to the appropriate

procedure in this section or in the seatbelt system section.

-

NOTE: If a dual stage driver or passenger airbag has deployed due to a crash event, the airbag requires manual deployment to make sure both stages and the active canister vent (if equipped) have deployed before scrapping the vehicle or disposing of the airbag.

Determine if the vehicle is equipped with dual stage driver or passenger airbags.

Refer to: Airbag and Seatbelt Pretensioner Supplemental Restraint System (SRS) - System Operation and Component Description (501-20B Supplemental Restraint System, Description and Operation).

-

REFER to: Disposal of Deployable Devices and

Pyrotechnic Devices That Require Manual Deployment in this procedure.

-

Seal the deployed air bag module(s) in the packaging

from the new air bag module(s) or a suitable polythene bag and dispose

of the deployed device.

-

If required, dispose of in accordance with local contaminated waste regulations.

-

If there are no local contaminated waste

regulations, dispose of the deployed device in the same manner as any

other part to be scrapped.

-

If required, dispose of in accordance with local contaminated waste regulations.

Disposal of Deployable Devices and Pyrotechnic Devices That Require Manual Deployment

NOTE: Safety and environmental concerns require consideration and treatment of restraints system deployable and pyrotechnic devices when disposing of vehicles, deployable devices or pyrotechnic devices. Deploying deployable and pyrotechnic devices before scrapping a vehicle or the device eliminates the potential for hazardous exposures or reactions during processing. If special handling procedures are followed, deployable and pyrotechnic devices can be deployed safely and recycled with the vehicle, shipped separately to a recycling facility or disposed of safely.

-

To determine the deployable devices a vehicle is equipped with:

Refer to: Airbag and Seatbelt Pretensioner Supplemental Restraint System (SRS) - System Operation and Component Description (501-20B Supplemental Restraint System, Description and Operation).

-

A vehicle equipped with any of the following

deployable devices requires manual deployment of the devices before

scrapping the vehicle or component. For additional information, refer to

the appropriate portion of this procedure.

-

-

Driver airbag

-

Inflatable seatbelt inflators

-

Knee airbag

-

Passenger airbag

-

Seat side airbag

-

Safety Canopy®

-

Side air curtain

-

Driver airbag

-

To determine the pyrotechnic devices a vehicle is equipped with:

Refer to: Airbag and Seatbelt Pretensioner Supplemental Restraint System (SRS) - System Operation and Component Description (501-20B Supplemental Restraint System, Description and Operation).

-

A vehicle equipped with any of the following

pyrotechnic devices requires manual deployment of the devices before

scrapping the vehicle or component. For additional information, refer to

the appropriate portion of this procedure.

-

-

Inflatable seatbelt inflators

-

Seatbelt buckle pretensioners

-

Seatbelt retractor pretensioners

-

Seatbelt anchor pretensioners

-

Adaptive load-limiting retractors

-

Deployable steering column

-

Inflatable seatbelt inflators

-

NOTE: If a dual stage driver or passenger airbag has deployed due to a crash event, the airbag requires manual deployment to make sure both stages and the active canister vent (if equipped) have deployed before scrapping the vehicle or disposing of the airbag.

To determine if a vehicle is equipped with dual stage driver or passenger airbags:

Refer to: Airbag and Seatbelt Pretensioner Supplemental Restraint System (SRS) - System Operation and Component Description (501-20B Supplemental Restraint System, Description and Operation).

-

If a dual stage driver or passenger airbag has

deployed due to a crash event, the airbag requires manual deployment to

make sure both stages and the active canister vent have deployed before

scrapping the vehicle or disposing of the airbag. Refer to Driver,

Passenger, Knee, Side Curtain and Seat Side Airbags - Remote Deployment

in this procedure.

Driver, Passenger, Knee, Side Curtain and Seat Side Airbags - Remote Deployment

NOTE: For airbags with multiple loops, deploy all of the loops on the airbag.

NOTE: Some driver and passenger front airbags have 2 deployment stages and an active canister vent. After a collision it is possible that Stage 1 has deployed and Stage 2 and the active canister vent have not. If a front airbag has deployed, it is mandatory the front airbag be remotely deployed using the appropriate airbag disposal procedure.

NOTE: A typical airbag disposal is shown that is similar for all vehicles.

-

-

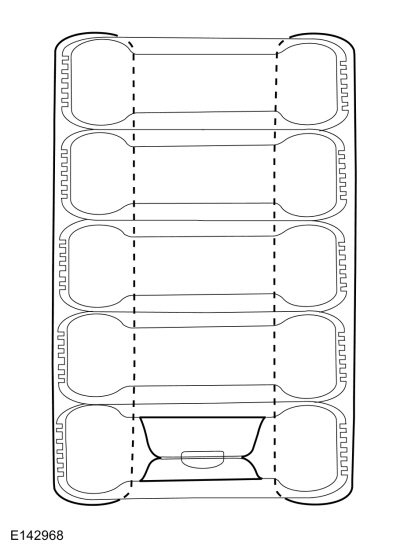

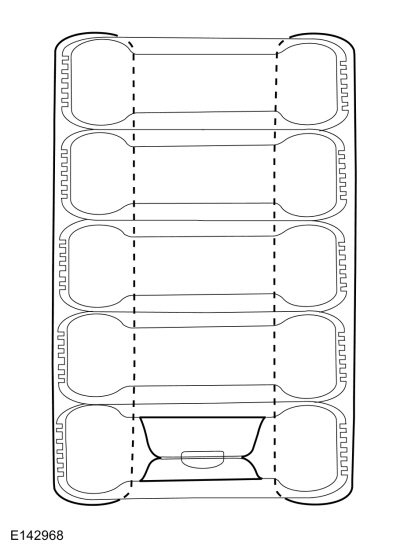

NOTE: The tires must be of sufficient size to accommodate the airbag.

Obtain a tire and wheel assembly and 4 additional tires (without wheels) of the same size.

-

With the tire and wheel assembly on the bottom, stack the tires.

-

Securely tie all of the tires together.

-

|

-

Depower the SRS

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the airbag. Refer to the appropriate procedure in this section.

-

If the airbag does not have a hard-wired pigtail:

-

For vehicles being scrapped, cut each of the

airbag wires near the electrical connector that connects to the vehicle

wire harness.

-

For vehicles not being scrapped, acquire the

appropriate wiring pigtail kit. REFER to the Wiring Diagrams manual.

-

For vehicles being scrapped, cut each of the

airbag wires near the electrical connector that connects to the vehicle

wire harness.

-

Remove any sheathing (if present) and strip the insulation from the ends of the cut wires.

-

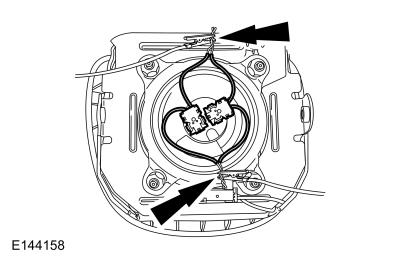

NOTE: Typical driver airbag with 2 loops shown, other airbags with multiple loops or multiple features (canister vent, active tether) similar.

For airbags with multiple loops, twist together a wire from each loop then repeat for the remaining wires from each loop.

.jpg) |

-

-

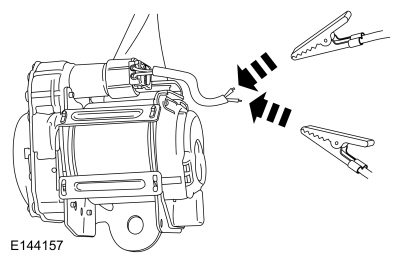

Make a jumper harness to deploy the airbag

module by obtaining 2 wires (20 gauge minimum) at least 9.14 m (30 ft).

-

At one end of the jumper harness, connect the wires together.

-

Make a jumper harness to deploy the airbag

module by obtaining 2 wires (20 gauge minimum) at least 9.14 m (30 ft).

-

Using the end of the jumper harness where the wires

are not connected together, attach each wire of the jumper harness to

each wire of the airbag or to the twisted-together wires if multiple

loops. Use tape or other insulating material to make sure the leads do

not make contact with each other.

|

-

NOTE: Make sure the airbag connections are maintained.

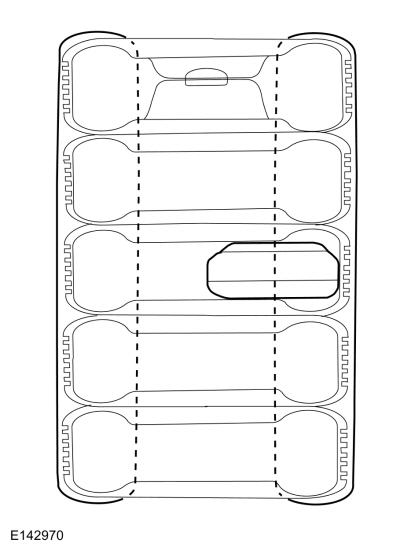

For driver airbags, with the stack of tires upright and the wheel on the bottom, carefully place the driver airbag, with the trim cover facing up, on the wheel.

|

-

NOTE: Make sure the airbag connections are maintained.

-

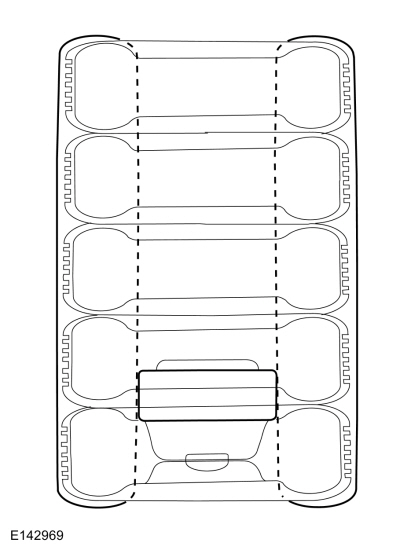

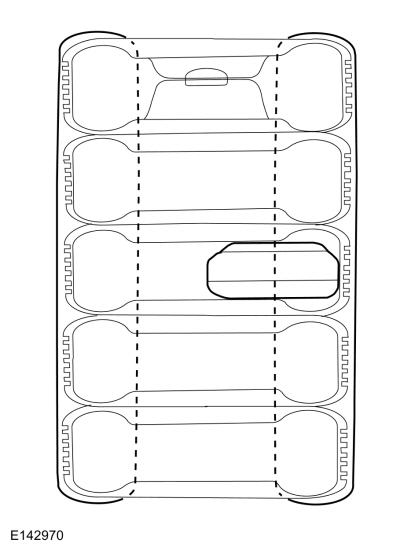

For passenger, knee and seat side airbags, tip the stack of tires on its side.

-

Place the airbag inside the center tire, making

sure that there are 2 tires beneath the tire containing the airbag and 2

tires (including the tire and wheel assembly) above the tire containing

the airbag.

-

Place the tire stack upright, with the wheel on top.

-

For passenger, knee and seat side airbags, tip the stack of tires on its side.

|

-

Remain at least 9.14 m (30 ft) away from the airbag.

-

From the end of the jumper harness that is not

connected to the airbag, disconnect the 2 wires of the jumper harness

from each other.

-

Deploy the airbag by touching the ends of the 2

wires of the jumper harness to the terminals of a 12-volt battery.

-

To allow for cooling, wait at least 10 minutes before approaching the deployed airbag.

-

Dispose of the deployed airbag in the same manner as any other part to be scrapped.

Seatbelt Anchor-Buckle-Retractor Pretensioners, Adaptive Load Limiting Retractors and Seatbelt Inflators - Remote Deployment

-

-

NOTE: The tires must be of sufficient size to accommodate the seatbelt anchor, buckle, retractor or inflator.

Obtain a tire and wheel assembly and 4 additional tires (without wheels) of the same size.

-

With the tire and wheel assembly on the bottom, stack the tires.

-

Securely tie all of the tires together.

-

|

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the seatbelt anchor, buckle, retractor or

inflator. Refer to the appropriate procedure in the seatbelt system

section.

-

If the seatbelt anchor, buckle, retractor or

inflator does not have a hard-wired pigtail, cut each of the wires near

the electrical connector that connects to the vehicle wire harness.

-

When deploying a seatbelt buckle pretensioner,

install a nut and bolt of sufficient length and the same diameter used

to retain it to the seat.

-

Remove any sheathing (if present) and strip the insulation from the ends of the cut wires.

-

-

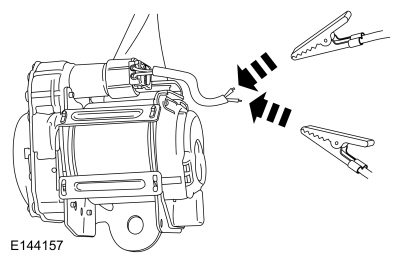

Make a jumper harness to deploy the seatbelt

anchor, buckle, retractor or inflator by obtaining 2 wires (20 gauge

minimum) at least 9.14 m (30 ft).

-

At one end of the jumper harness, connect the wires together.

-

Make a jumper harness to deploy the seatbelt

anchor, buckle, retractor or inflator by obtaining 2 wires (20 gauge

minimum) at least 9.14 m (30 ft).

-

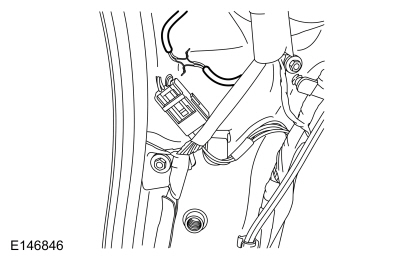

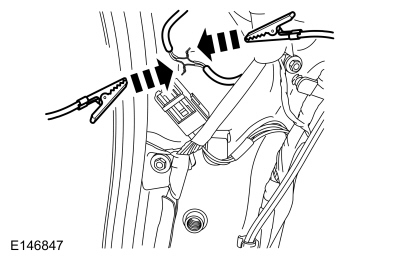

NOTE: Typical seatbelt retractor pretensioner shown, other seatbelt anchor pretensioners, buckle pretensioners, load-limiting retractors and seatbelt inflators similar.

Using the end of the jumper harness where the wires are not connected together, attach each wire of the jumper harness to each wire of the seatbelt anchor, buckle, retractor or inflator. Use tape or other insulating material to make sure the leads do not make contact with each other.

|

-

NOTE: Make sure the airbag connections are maintained.

-

Tip the stack of tires on its side.

-

Place the seatbelt anchor, buckle, retractor or

inflator inside the center tire, making sure that there are 2 tires

beneath the tire containing the airbag and 2 tires (including the tire

and wheel assembly) above the tire containing the airbag.

-

Place the tire stack upright, with the wheel on top.

-

Tip the stack of tires on its side.

|

-

Remain at least 9.14 m (30 ft) away from the seatbelt anchor, buckle, retractor or inflator.

-

From the end of the jumper harness that is not

connected to the seatbelt anchor, buckle, retractor or inflator,

disconnect the 2 wires of the jumper harness from each other.

-

Deploy the seatbelt anchor, buckle, retractor or

inflator by touching the ends of the 2 wires of the jumper harness to

the terminals of a 12-volt battery.

-

To allow for cooling, wait at least 10 minutes

before approaching the deployed seatbelt anchor, buckle, retractor or

inflator.

-

Dispose of the deployed seatbelt anchor, buckle,

retractor or inflator in the same manner as any other part to be

scrapped.

Seatbelt Anchor-Buckle-Retractor Pretensioners, and Adaptive Load Limiting Retractors - In-Vehicle Deployment

-

Depower the SRS

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Access the seatbelt anchor, buckle or retractor

electrical connectors. Refer to the appropriate procedure in the

seatbelt system section.

-

Cut each of the seatbelt anchor, buckle or retractor wires, leaving at least 101.6 mm (4 in) to work with.

-

Remove any sheathing (if present) and strip the insulation from the ends of the cut wires.

-

-

Make a jumper harness to deploy the seatbelt

anchor, buckle or retractor by obtaining 2 wires (20 gauge minimum) at

least 9.14 m (30 ft).

-

At one end of the jumper harness, connect the wires together.

-

Make a jumper harness to deploy the seatbelt

anchor, buckle or retractor by obtaining 2 wires (20 gauge minimum) at

least 9.14 m (30 ft).

-

NOTE: Typical seatbelt retractor pretensioner shown, other seatbelt anchor pretensioners, buckle pretensioners and load-limiting retractors are similar.

Using the end of the jumper harness where the wires are not connected together, attach each wire of the jumper harness to each wire of the seatbelt anchor, buckle or retractor. Use tape or other insulating material to make sure the leads do not make contact with each other.

|

-

Remain at least 9.14 m (30 ft) away from the seatbelt anchor, buckle or retractor.

-

Remain at least 9.14 m (30 ft) away from the seatbelt anchor, buckle, retractor or inflator.

-

From the end of the jumper harness that is not

connected to the seatbelt anchor, buckle or retractor, disconnect the 2

wires of the jumper harness from each other.

-

Deploy the seatbelt anchor, buckle or retractor by

touching the ends of the 2 wires of the jumper harness to the terminals

of a 12-volt battery.

-

To allow for cooling, wait at least 10 minutes

before approaching the deployed seatbelt anchor, buckle or retractor.

-

Dispose of the deployed seatbelt anchor, buckle or

retractor in the same manner as any other part to be scrapped.

Safety Canopy® and Side Air Curtains - In-Vehicle Deployment

NOTE: The Safety Canopy® deployment for a scrapped vehicle occurs in its installed position in the vehicle.

NOTE: A typical Safety Canopy® disposal is shown.

-

Depower the SRS

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Access the Safety Canopy® /side air curtain

electrical connectors. For additional information, refer to the

appropriate procedure in this section.

-

Cut each of the Safety Canopy® /side air curtain wires, leaving at least 101.6 mm (4 in).

-

Remove any sheathing (if present) and strip the insulation from the ends of the cut wires.

-

NOTE: Typical Safety Canopy® /side air curtain with 2 loops shown, other Safety Canopy® /side air curtains with 2 loops are similar.

For Safety Canopy® /side air curtains with multiple loops, twist together a wire from each loop then repeat for the remaining wires from each loop.

|

-

-

Make a jumper harness to deploy the Safety

Canopy®/side air curtains by obtaining 2 wires (20 gauge minimum) at

least 9.14 m (30 ft).

-

At one end of the jumper harness, connect the wires together.

-

Make a jumper harness to deploy the Safety

Canopy®/side air curtains by obtaining 2 wires (20 gauge minimum) at

least 9.14 m (30 ft).

-

Using the end of the jumper harness where the wires

are not connected together, attach each wire of the jumper harness to

each wire of the Safety Canopy® /side air curtain or to the

twisted-together wires if multiple loops. Use tape or other insulating

material to make sure the leads do not make contact with each other.

|

-

From the end of the jumper harness that is not

connected to the Safety Canopy® /side air curtain, disconnect the 2

wires of the jumper harness from each other.

-

Deploy the Safety Canopy® /side air curtain by

touching the ends of the 2 wires of the jumper harness to the terminals

of a 12-volt battery.

-

To allow for cooling, wait at least 10 minutes

before approaching the deployed Safety Canopy® /side air curtain.

-

Dispose of the deployed Safety Canopy® /side air

curtain in the same manner as any other part to be scrapped.

Deployable Steering Column - In-Vehicle Deployment

-

Depower the SRS

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

NOTE: It may be necessary to lower or remove the deployable steering column from the instrument panel to access the deployable steering column electrical connector.

Access the deployable steering column electrical connector.

-

NOTE: If the deployable steering column does not have a hard-wired pigtail, cut the wires and connector(s) from the vehicle wire harness and reconnect to the deployable steering column.

Cut each of the deployable steering column wires, leaving at least 101.6 mm (4 in) to work with.

-

Remove any sheathing (if present) and strip the insulation from the ends of the cut wires.

-

-

Make a jumper harness to deploy the deployable

steering column by obtaining 2 wires (20 gauge minimum) at least 9.14 m

(30 ft).

-

At one end of the jumper harness, connect the wires together.

-

Make a jumper harness to deploy the deployable

steering column by obtaining 2 wires (20 gauge minimum) at least 9.14 m

(30 ft).

-

Using the end of the jumper harness where the wires

are not connected together, attach each wire of the jumper harness to

each wire of the deployable steering column. Use tape or other

insulating material to make sure the leads do not make contact with each

other.

.jpg) |

-

Remain at least 9.14 m (30 ft) away from the deployable steering column.

-

From the end of the jumper harness that is not

connected to the deployable steering column, disconnect the 2 wires of

the jumper harness from each other.

-

Deploy the deployable steering column by touching

the ends of the 2 wires of the jumper harness to the terminals of a

12-volt battery.

-

To allow for cooling, wait at least 10 minutes before approaching the deployed steering column.

-

Dispose of the deployed steering column in the same manner as any other part to be scrapped.

Inspection and Repair after a Supplemental Restraint System (SRS) Deployment. General Procedures

Inspection and Repair after a Supplemental Restraint System (SRS) Deployment. General Procedures

Inspection

WARNING:

If a vehicle has been in a crash, inspect the Restraints

Control Module (RCM) and impact sensor mounting areas for any damage or

deformation...

Supplemental Restraint System (SRS) Depowering. General Procedures

Supplemental Restraint System (SRS) Depowering. General Procedures

Depower

WARNING:

Incorrect repair techniques or actions can cause an

accidental Supplemental Restraint System (SRS) deployment. Never

compromise or depart from these instructions...

Other information:

Lincoln Nautilus 2018-2026 Owners Manual: Tire Pressure Monitoring System – Troubleshooting

Tire Pressure Monitoring System – Warning Lamps The low tire pressure warning lamp has combined functions, as it warns you when your tires need air, and when the system is no longer capable of functioning as intended. Tire Pressure Monitoring System – Information Messages ..

Lincoln Nautilus 2018-2026 Service Manual: Evaporator Core Leak Check. General Procedures

Inspection Recover the refrigerant. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information, General Procedures). Disconnect the evaporator from the A/C system. Refer to the appropriate removal and installation section in Group 412 for the procedure. Use the correct adapters with the A/C Serv..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Anti-Theft Alarm System Settings. Security – Troubleshooting

- Autounlock and Autolock

- USB Ports

- New on site

- Most important about car

Programming the Garage Door Opener to Your Garage Door Opener Motor