Lincoln Nautilus: Rear Disc Brake / Rear Brake Flexible Hose. Removal and Installation

Removal

NOTICE: Do not spill brake fluid on painted or plastic surfaces or damage to the surface may occur. If brake fluid is spilled onto a painted or plastic surface, immediately wash the surface with water.

NOTE: Removal steps in this procedure may contain installation details.

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

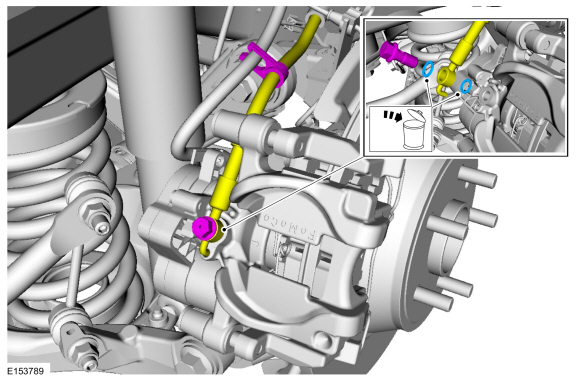

Remove the flow bolt, disconnect the brake hose and

detach the routing bracket from the wiring harness. Discard the washers.

Torque: 18 lb.ft (25 Nm)

|

-

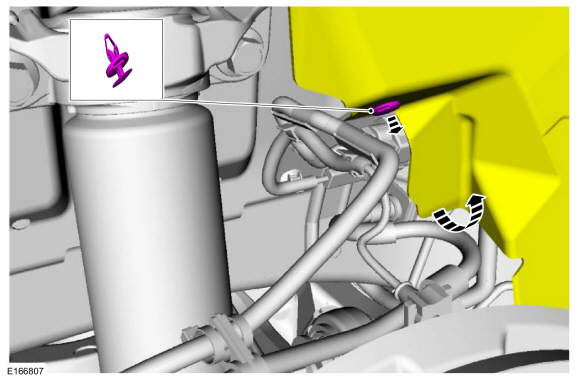

Remove the pin-type retainer and position the splash shield aside.

|

-

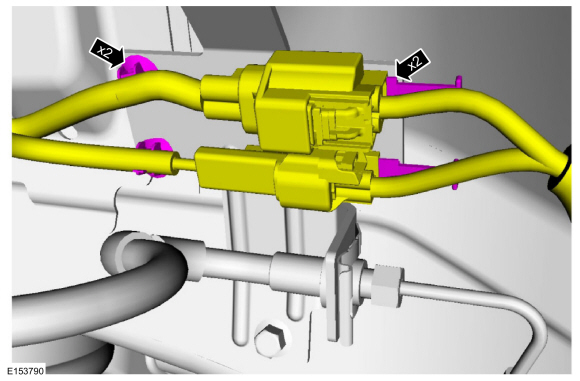

Detach the pin-type retainers and the electrical connectors from the brake hose bracket.

|

-

Remove the brake flexible hose.

-

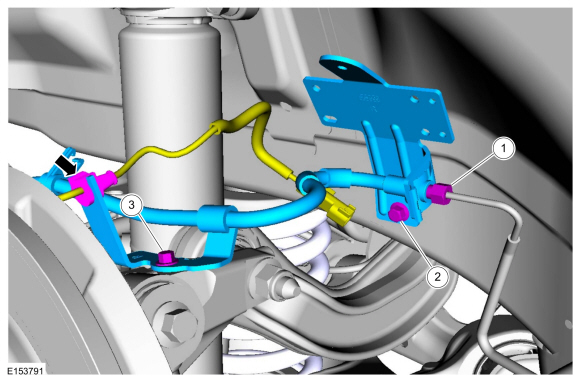

Disconnect the brake tube.

Torque: 159 lb.in (18 Nm)

-

Remove the bolt.

Torque: 22 lb.ft (30 Nm)

-

Remove the bolt, detach the wheel speed sensor wiring and remove the brake flexible hose.

Torque: 124 lb.in (14 Nm)

-

Disconnect the brake tube.

|

Installation

-

To install, reverse the removal procedure.

-

Bleed the brake system.

Refer to: Brake System Pressure Bleeding (206-00 Brake System - General Information, General Procedures).

Brake Pads. Removal and Installation

Brake Pads. Removal and Installation

Special Tool(s) /

General Equipment

Brake Caliper Piston Retractor

Materials

Name

Specification

Motorcraft® DOT 4 LV High Performance Motor Vehicle Brake FluidPM-20

WSS-M6C65-A2

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTE:

Removal steps in this procedure may contain installation details...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Hood Alignment. General Procedures

Inspection NOTE: Removal steps in this procedure may contain installation details. Inspect the hood-to-body dimensions. Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation). All alignments Open the hood. NOTE: Support the hood before removing the struts. F..

Lincoln Nautilus 2018-2026 Service Manual: Seatbelt Maintenance. General Procedures

Inspection WARNING: All seatbelt components must be inspected and corrected as part of any collision repair. Inspect all seatbelt components as prescribed by Seatbelt Procedure After a Collision found in Section 501-20A General Procedures of this manual. Failure to follow this instruction may result in incorrect operation of the seatbelt system and increase the risk of serious per..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Changing the 12V Battery

- Drive Mode Control

- Massage Seats

- New on site

- Most important about car

Changing a Flat Tire

WARNING: If the tire pressure monitor sensor becomes damaged it may not function.

Note: The use of tire sealant may damage your tire pressure monitoring system and should only be used in roadside emergencies. If you must use a sealant, use the Tire Mobility Kit sealant. Replace the tire pressure monitoring system sensor and valve stem on the wheel by an authorized dealer after use of the sealant.

Note: The tire pressure monitoring system indicator light will illuminate when the spare tire is in use. To restore the full function of the monitoring system, all road wheels equipped with tire pressure monitoring sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply the brake hea