Lincoln Nautilus: Engine System - General Information / Cylinder Block Distortion. General Procedures

Lincoln Nautilus 2018-2026 Service Manual / Powertrain / Engine / Engine System - General Information / Cylinder Block Distortion. General Procedures

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

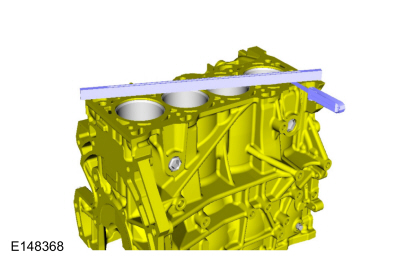

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

Use a Straightedge and a Feeler Gauge Set to inspect the cylinder block for flatness.

Use the General Equipment: Feeler Gauge

|

Cylinder Block Core Plug Replacement. General Procedures

Cylinder Block Core Plug Replacement. General Procedures

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock 262TA-26

WSK-M2G351-A6

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

Cylinder Bore Taper. General Procedures

Cylinder Bore Taper. General Procedures

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

Other information:

Lincoln Nautilus 2018-2026 Owners Manual: Under Hood Overview - 2.0L

Engine coolant reservoir. See Checking the Coolant. Engine oil dipstick. See Engine Oil Dipstick Overview. Engine oil filler cap. See Adding Engine Oil. Brake fluid reservoir. See Checking the Brake Fluid. Battery. See Changing the 12V Battery...

Lincoln Nautilus 2018-2026 Service Manual: Differential Draining and Filling. General Procedures

Materials Name Specification Motorcraft® Disconnect Rear Drive Unit FluidXY-75W-QL - Draining With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation)...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Autounlock and Autolock

- Changing the 12V Battery

- Engine Oil Capacity and Specification - 2.0L

- New on site

- Most important about car

USB Ports

Locating the USB Ports

Data Transfer USB Ports

The USB Ports could be in the following locations:

On the lower instrument panel. Inside the media bin. Inside the center console.Note: These USB ports can also charge devices.

Copyright © 2026 www.linautilus.com