Lincoln Nautilus: Rear End Sheet Metal Repairs / Front Floor Panel. Removal and Installation

Special Tool(s) / General Equipment

| Scraper for Straight Edges | |

| Hot Air Gun | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Roof and body side removed for clarity.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the instrument panel.

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

-

Rmove the front floor panel upper front crossmember.

Refer to: Front Floor Panel Upper Front Crossmember (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Rmove the front floor panel upper rear crossmember.

Refer to: Front Floor Panel Upper Rear Crossmember (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Position the carpet and all wiring harnesses away from the working area.

-

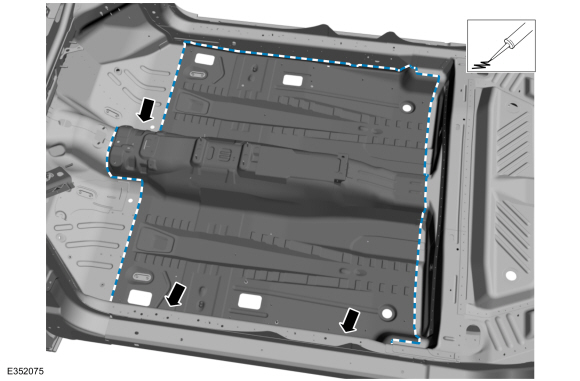

Remove the locally obtained NVH (noise, vibration and harshness) mastic pads.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

.jpg) |

-

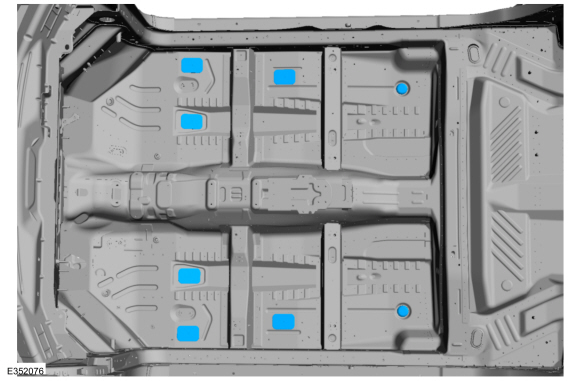

Remove the seam sealer.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

.jpg) |

-

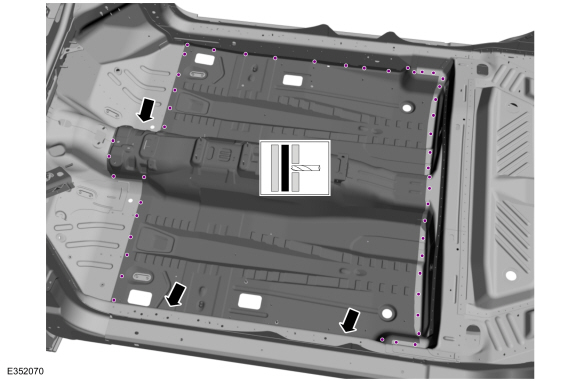

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Pay particular attention to the location of adhesives and sealers to aid in installation.

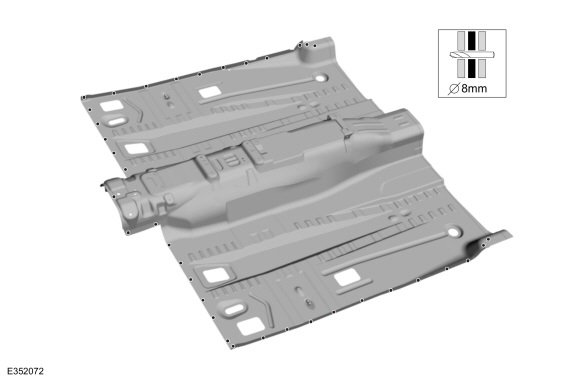

Remove the front floor panel.

.jpg) |

Installation

NOTE: Roof and body side removed for clarity.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

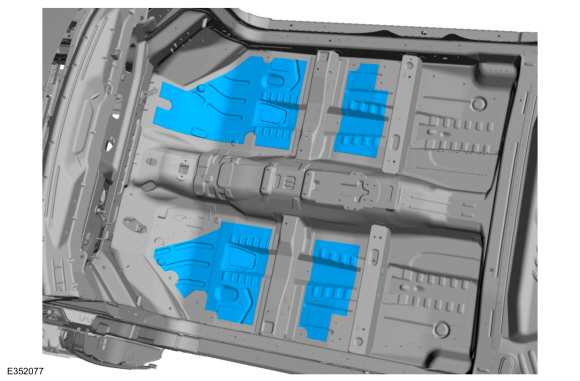

Drill plug welds holes in the replacement front floor panel.

Use the General Equipment: 8 mm Drill Bit

|

-

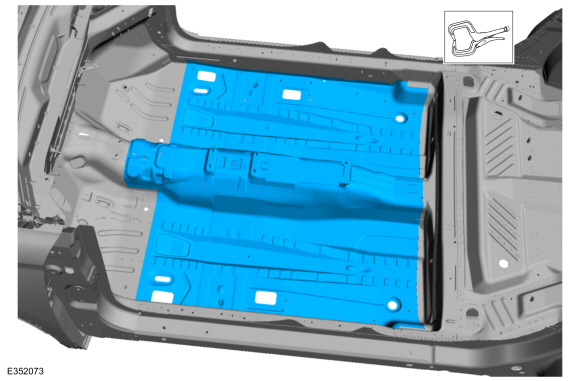

Install, properly position and clamp the front floor panel.

Use the General Equipment: Locking Pliers

|

-

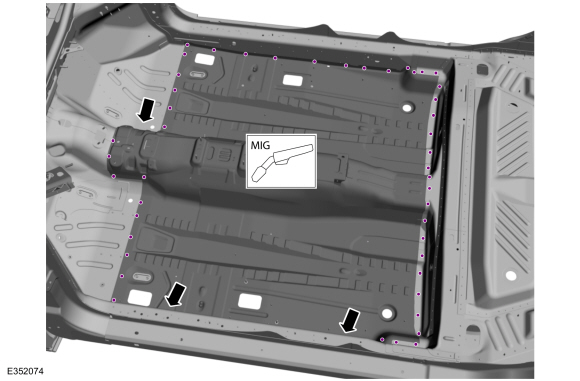

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Dress all welds as required using typical metal finishing techniques.

-

Seam Sealing:

All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

|

-

Install new or transfer the floor panel plugs.

|

-

Install locally obtained NVH mastic pads.

|

-

Refinish the entire repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition all wiring harnesses and the carpet to original locations.

-

Install the instrument panel.

Refer to: Instrument Panel (501-12 Instrument Panel and Console, Removal and Installation).

-

Install the front floor panel upper front crossmenber.

Refer to: Front Floor Panel Upper Front Crossmember (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the front floor panel upper rear crossmenber.

Refer to: Front Floor Panel Upper Rear Crossmember (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Front Floor Panel Bracket and Support. Removal and Installation

Front Floor Panel Bracket and Support. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

The following components are available separately...

Other information:

Lincoln Nautilus 2018-2026 Owners Manual: Removing Your Vehicle From Storage

When your vehicle is ready to come out of storage, do the following: We recommend that you change the engine oil before you use your vehicle again. Wash your vehicle to remove any dirt or grease film build-up on window surfaces. Check windshield wipers for any deterioration...

Lincoln Nautilus 2018-2026 Service Manual: Air Inlet Door Actuator. Removal and Installation

Removal Remove the instrument panel. Refer to: Instrument Panel (501-12) . Disconnect the electrical connector, remove the retainers and the air inlet door actuator. Installation To install, reverse the removal procedure...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Normal Scheduled Maintenance

- Opening the Liftgate

- Fuel Quality

- New on site

- Most important about car

Traction Control

How Does Traction Control Work

If your vehicle begins to slide, the system applies the brakes to individual wheels and, when needed, reduces power at the same time. If the wheels spin when accelerating on slippery or loose surfaces, the system reduces power in order to increase traction.

Switching Traction Control On and Off

WARNING: The stability and traction control light illuminates steadily if the system detects a failure. Make sure you did not manually disable the traction control system using the information display controls or the switch. If the stability control and traction control light is still illuminating steadily, have the system serviced by an authorized dealer immediately. Operating your vehicle with the traction co