Lincoln Nautilus: Rear End Sheet Metal Repairs / Rear Floor Panel Section. Removal and Installation

Special Tool(s) /

General Equipment

| Spherical Cutter |

| Grinder |

| Air Body Saw |

| MIG/MAG Welding Equipment |

| Spot Weld Drill Bit |

Materials

| Name |

Specification |

Flange Sealant

CU7Z-19B508-A |

WSS-M2G348-A11

|

Removal

-

Restore vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Reposition the carpeting and the wiring harness away from the working area.

-

Remove the following items:

-

Remove the rear bumper.

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

Remove the fuel tank (as equipped).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Remove the loadspace trim panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

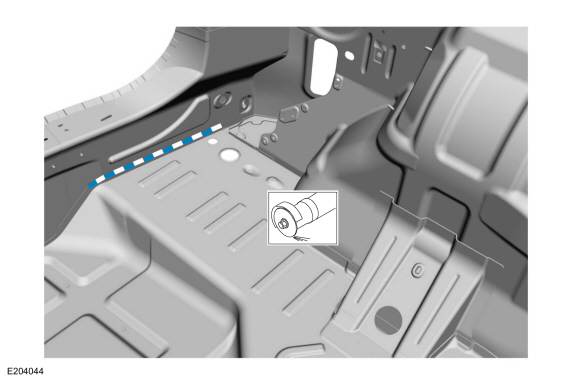

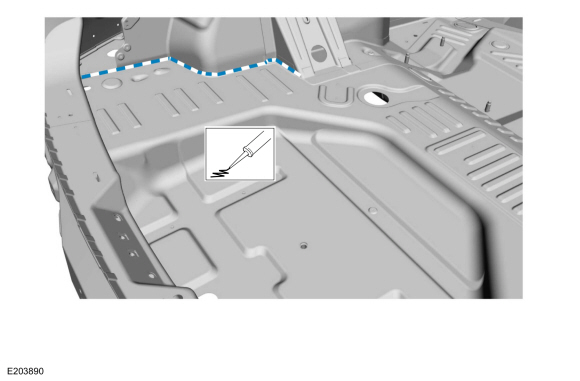

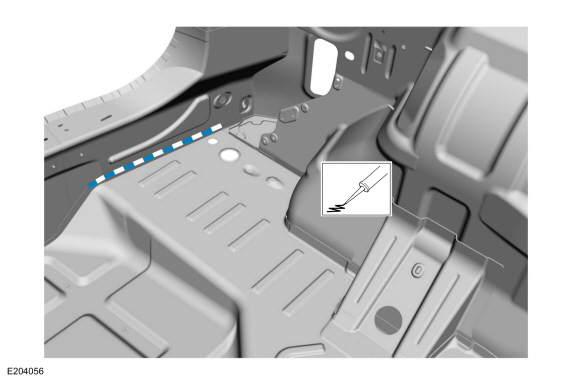

NOTE:

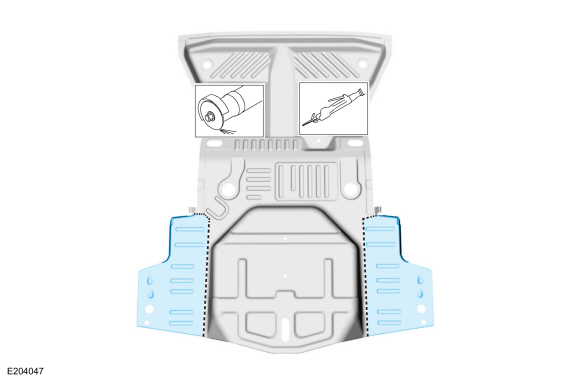

LH side shown, RH side similar.

-

Using a grinder with an abrasive disc or equivalent, remove the sealer along the floor pan rear flange.

Use the General Equipment: Grinder

-

Using a grinder with an abrasive disc or equivalent, remove the sealer along the floor pan flange.

Use the General Equipment: Grinder

-

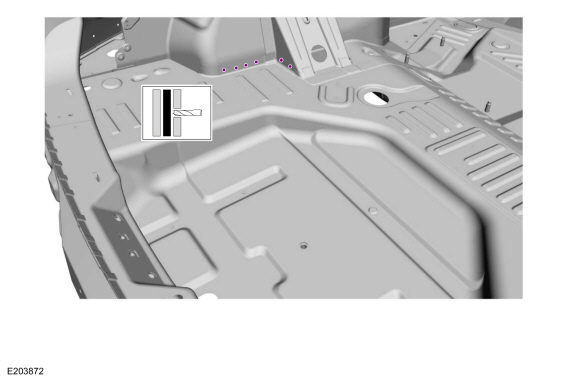

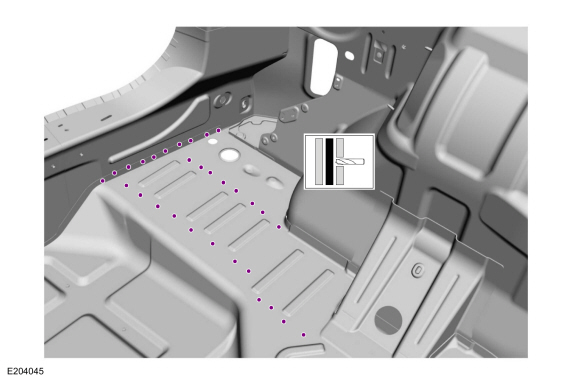

Remove the spot welds along the floor pan wheelhouse flange.

Use the General Equipment: Spot Weld Drill Bit

-

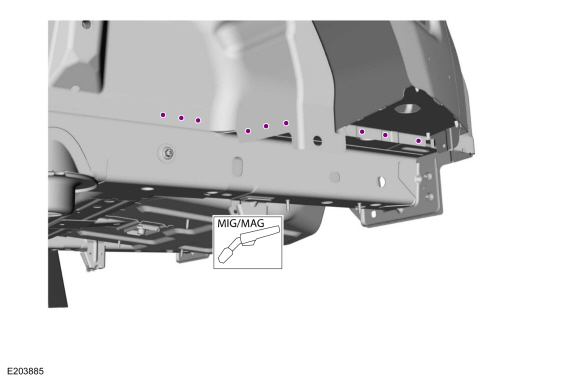

Remove the spot welds along the rear flange and frame rail area.

Use the General Equipment: Spot Weld Drill Bit

-

Remove the spot welds along the floor pan lower wheelhouse flange.

-

NOTICE:

Cut through floor panel only, do not cut into reinforcements or crossmembers.

NOTE:

Back panel removed from view for clarity.

Cut and remove the floor panel section as indicated.

Use the General Equipment: Spherical Cutter

Installation

-

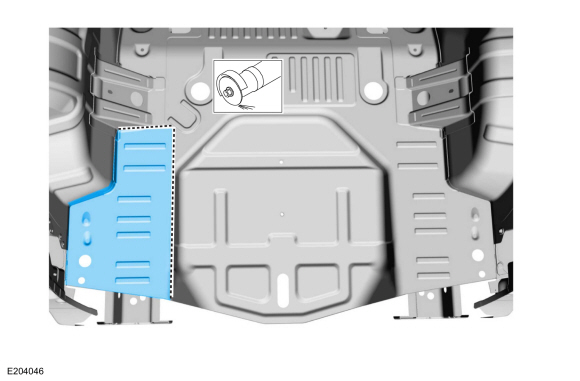

Create sectioning piece from the replacement part as required.

Use the General Equipment: Spherical Cutter

Use the General Equipment: Air Body Saw

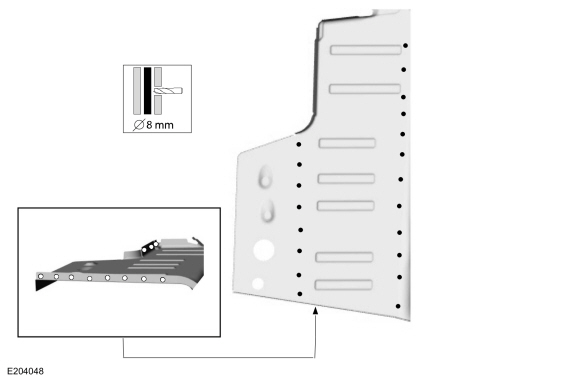

NOTE:

LH side shown, RH side similar.

-

Drill holes for plug welding in the replacement section.

-

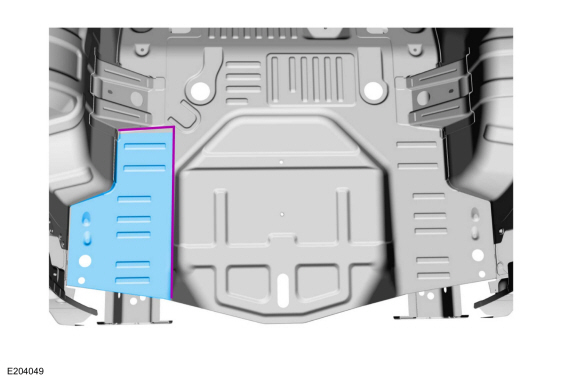

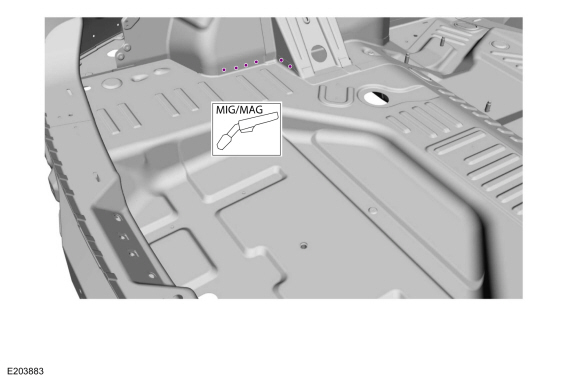

Install the replacement section and seam weld.

Use the General Equipment: MIG/MAG Welding Equipment

-

Weld the floor panel to the side member and rear flange.

Use the General Equipment: MIG/MAG Welding Equipment

-

Weld the floor panel at the wheelhouse.

Use the General Equipment: MIG/MAG Welding Equipment

-

Weld the lower floor panel flange on the affected side.

Use the General Equipment: MIG/MAG Welding Equipment

-

Metal finish as required using typical metal finishing techniques.

-

Refinish using a Ford approved paint system.

-

Apply sealer to the floor panel wheelhouse flange.

Material: Flange Sealant

/ CU7Z-19B508-A

(WSS-M2G348-A11)

-

Apply sealer to the floor panel rear flange.

-

Sealing work: All areas must be sealed to production level.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition the carpeting and the wiring harness.

-

Install the following items:

-

Install the fuel tank (as equipped).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Install the rear bumper.

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

-

Install the loadspace trim panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Special Tool(s) /

General Equipment

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Removal

NOTICE:

The rear side member(s) are constructed of Dual Phase

(DP) 800 steel and cannot be sectioned...

Other information:

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated. Verify the cylinder

bore is within the wear limit. The difference indicates the cylinder

bore taper...

Setting a Destination Using the Text Entry Screen

Press the search bar at the top of the

screen.

Enter your destination using the

keyboard.

Press Search.

Select a destination from the list.

Press Start to begin navigation.

Setting a Destination Using the Map Screen

Press and hold on the map to place a pin at

that location...

.jpg)

.jpg)

Rear Floor Panel Reinforcement. Removal and Installation

Rear Floor Panel Reinforcement. Removal and Installation Rear Side Member. Removal and Installation

Rear Side Member. Removal and Installation