Lincoln Nautilus: Rear End Sheet Metal Repairs / Rear Floor Panel Reinforcement. Removal and Installation

Special Tool(s) / General Equipment

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the rear Subframe.

Refer to: Rear Subframe - AWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

Refer to: Rear Subframe - FWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

-

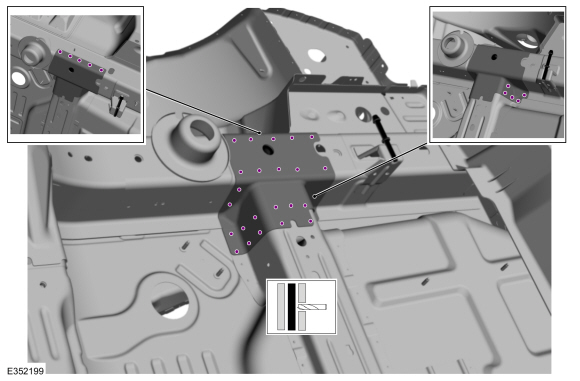

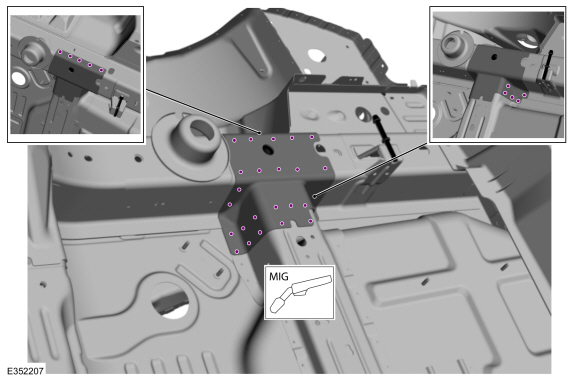

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

On Both Sides:

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

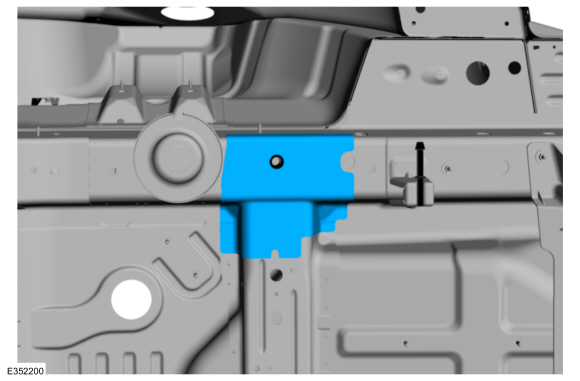

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

On Both Sides:

Remove the panel.

|

-

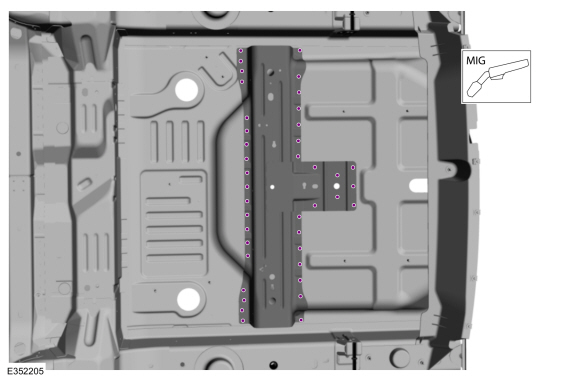

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

.jpg) |

-

Remove the Rear Floor Panel Reinforcement.

|

Installation

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

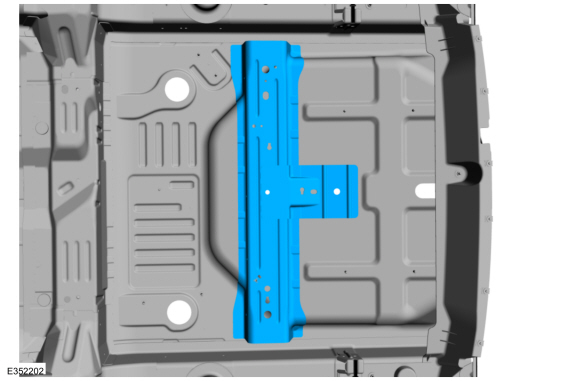

Drill plug weld holes in the replacement reinforcement.

Use the General Equipment: 8 mm Drill Bit

.jpg) |

-

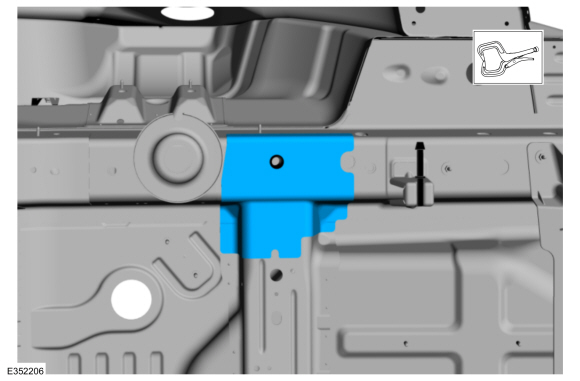

Install, properly position, clamp the replacement reinforcement.

Use the General Equipment: Locking Pliers

.jpg) |

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

On Both Sides:

Install, properly position, clamp the replacement panel.

Use the General Equipment: Locking Pliers

|

-

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

On Both Sides:

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Dress all welds as required using typical metal finishing techniques.

-

Seam Sealing:

All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the entire repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the rear subframe.

Refer to: Rear Subframe - AWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

Refer to: Rear Subframe - FWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

-

Repowering the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Rear Floor Panel Crossmember. Removal and Installation

Rear Floor Panel Crossmember. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Rear Floor Panel Section. Removal and Installation

Rear Floor Panel Section. Removal and Installation

Special Tool(s) /

General Equipment

Spherical Cutter

Grinder

Air Body Saw

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Materials

Name

Specification

Flange SealantCU7Z-19B508-A

WSS-M2G348-A11

Removal

Restore vehicle to pre-accident dimensions, if required...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Roof Opening Panel. Diagnosis and Testing

DTC Chart: Roof Opening Panel Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). BCM Module DTC Chart DTC Description Action B12F4:12 Vehicle Speed Output: Circuit Short To Bat..

Lincoln Nautilus 2018-2026 Service Manual: Clockspring. Removal and Installation

Removal WARNING: The following procedure prescribes critical repair steps required for correct restraint system operation during a crash. Follow all notes and steps carefully. Failure to follow step instructions may result in incorrect operation of the restraint system and increases the risk of serious personal injury or death in a crash. NOTE: Removal steps in this procedure ..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Switching the Lane Keeping System On and Off. Switching the Lane Keeping System Mode

- Changing the 12V Battery

- Interior Lamp Function. Adjusting the Instrument Panel Lighting Brightness. Ambient Lighting. Interior Lighting – Troubleshooting

- New on site

- Most important about car

Clearing the Garage Door Opener. Reprogramming the Garage Door Opener. Garage Door Opener Radio Frequencies

Clearing the Garage Door Opener