Lincoln Nautilus: Rear End Sheet Metal Repairs / Rear Side Member. Removal and Installation

Lincoln Nautilus 2018-2026 Service Manual / Body and Paint / Body and Paint / Rear End Sheet Metal Repairs / Rear Side Member. Removal and Installation

Special Tool(s) / General Equipment

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit |

Removal

NOTICE: The rear side member(s) are constructed of Dual Phase (DP) 800 steel and cannot be sectioned. Side member assembly must be replaced at factory joints.

-

Restore vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the back panel.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the rear subframe, as equipped.

Refer to: Rear Subframe - AWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

Refer to: Rear Subframe - FWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

-

Remove the fuel tank, as equipped.

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Remove the back panel.

-

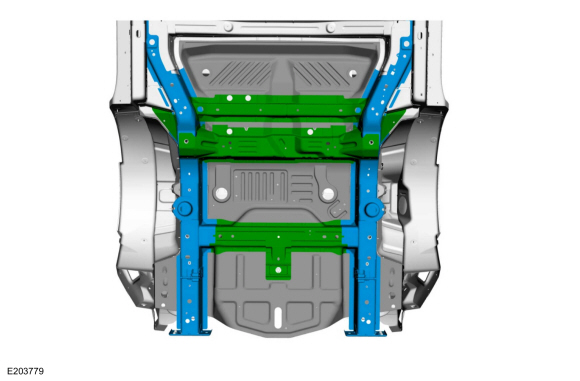

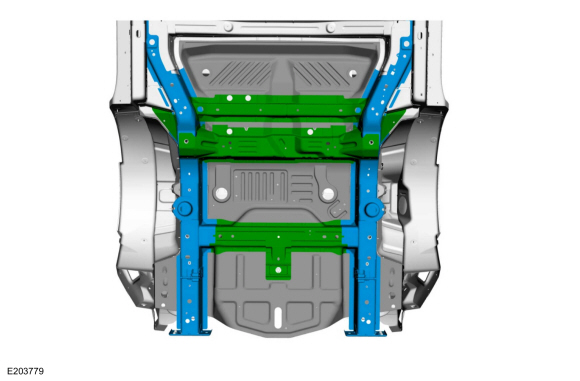

Overview of rear side member assembly.

|

-

Reposition the carpet and wiring harness away from the working area.

-

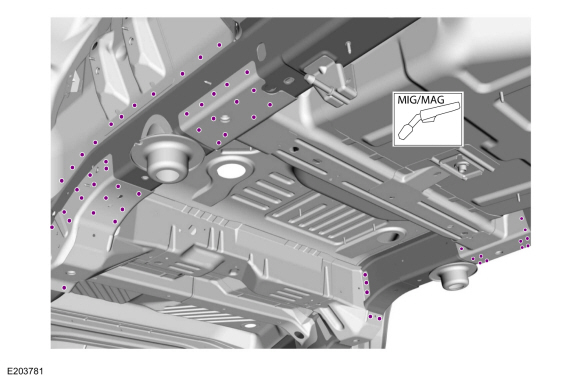

Remove the crossmember and reinforcement spot welds as required.

Use the General Equipment: Spot Weld Drill Bit

.jpg) |

Installation

-

Overview of rear side member assembly.

|

-

Weld the crossmember and reinforcements.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the following items:

-

Install the back panel.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the fuel tank, as equipped.

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.7L EcoBoost (238kW/324PS), Removal and Installation).

-

Install the rear subframe, as equipped.

Refer to: Rear Subframe - AWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

Refer to: Rear Subframe - FWD (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation).

-

Install the back panel.

-

Reposition the carpeting and wiring harness.

Rear Floor Panel Section. Removal and Installation

Rear Floor Panel Section. Removal and Installation

Special Tool(s) /

General Equipment

Spherical Cutter

Grinder

Air Body Saw

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Materials

Name

Specification

Flange SealantCU7Z-19B508-A

WSS-M2G348-A11

Removal

Restore vehicle to pre-accident dimensions, if required...

Rear Side Member Reinforcement Panel. Removal and Installation

Rear Side Member Reinforcement Panel. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Removal

NOTE:

Left hand (LH) side shown, right hand (RH) side similar...

Other information:

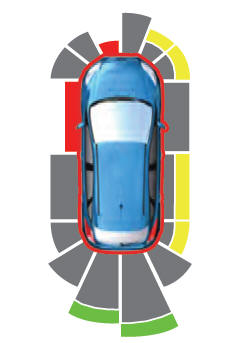

Lincoln Nautilus 2018-2026 Service Manual: Parking Aid - System Operation and Component Description. Description and Operation

System Operation Rear Only Parking Aid Camera System Diagram Item Description 1 Video signal 2 PCM 3 ABS Module 4 PSCM 5 GWM 6 APIM 7 BCM 8 PAM 9 Rear parking aid camera 10 TRM 11 With trailer tow 12 FDIM Network Message Chart BCM Net..

Lincoln Nautilus 2018-2026 Service Manual: Refrigerant Identification Testing. General Procedures

Activation NOTE: Use Refrigerant Identification Equipment to identify gas samples taken directly from the refrigeration system or storage containers prior to recovering or charging the refrigerant system. NOTE: Use Refrigerant Identification Equipment that conforms to SAE J1771 standard for R-134a or SAE J2912 standard identifies R-134a and R-1234yf. Follow the instructions in..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Normal Scheduled Maintenance

- Massage Seats

- Replacing the Rear Wiper Blades

- New on site

- Most important about car

Parking Aid Indicators. Parking Aids – Troubleshooting

Parking Aid Indicators

The system provides object distance indication through the information and entertainment display.

As the distance to the object decreases, the indicator waves and the lines move toward the vehicle icon. If there is no object detected, the distance indicator lines are grey.Copyright © 2026 www.linautilus.com