Lincoln Nautilus: Rear End Sheet Metal Repairs / Rear Side Member Reinforcement Panel. Removal and Installation

Special Tool(s) / General Equipment

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

Removal

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the rear floor panel.

Refer to: Rear Floor Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

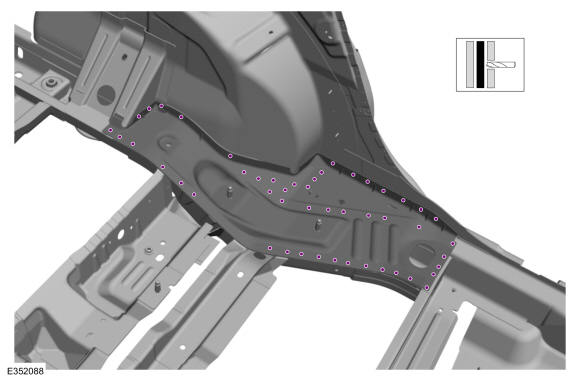

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the reinforcement.

Use the General Equipment: Spot Weld Drill Bit

.jpg) |

Installation

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Drill plug weld holes in the reinforcement panel.

Use the General Equipment: 8 mm Drill Bit

.jpg) |

-

Apply adhesive.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

.jpg) |

-

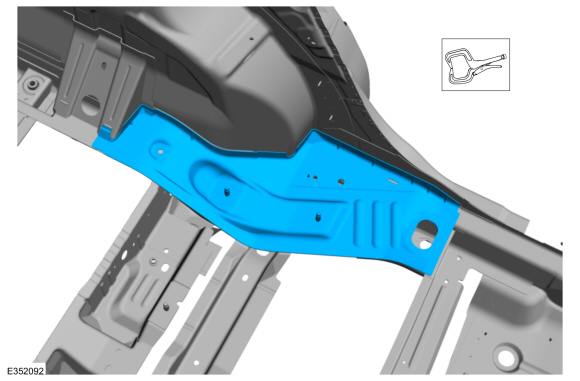

Install, properly position, clamp the replacement reinforcement.

Use the General Equipment: Locking Pliers

|

-

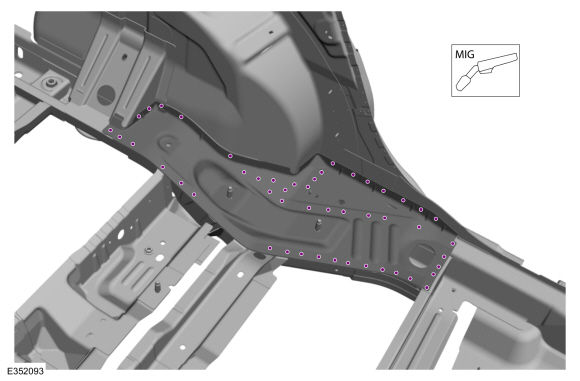

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Dress all welds as required using typical metal finishing techniques.

-

Refinish the entire repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the rear floor panel.

Refer to: Rear Floor Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Rear Side Member. Removal and Installation

Rear Side Member. Removal and Installation

Special Tool(s) /

General Equipment

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Removal

NOTICE:

The rear side member(s) are constructed of Dual Phase

(DP) 800 steel and cannot be sectioned...

Rear Suspension Bracket Reinforcement. Removal and Installation

Rear Suspension Bracket Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTE:

LH side shown, RH side similar...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Front Subframe. Removal and Installation

Special Tool(s) / General Equipment 014-3KLIFTTABLEPowertrain Lift Table Tie Rod End Remover Steering Wheel Holder Wooden Block Materials Name Specification Motorcraft® Threadlock 262TA-26 WSK-M2G351-A6 Removal NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems...

Lincoln Nautilus 2018-2026 Owners Manual: Declaration of Conformity

Radio Frequency Statement WARNING: Changes or modifications not expressively approved by the party responsible for compliance could void the user's authority to operate the equipment. The term "IC:" before the radio certification number only signifies that Industry Canada technical specifications were met...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Normal Scheduled Maintenance

- Replacing the Rear Wiper Blades

- Fuel Quality

- New on site

- Most important about car

Opening and Closing the Hood

Opening the Hood