Lincoln Nautilus: Climate Control System - General Information / Refrigerant System Tests - 2.0L EcoBoost (184kW/250PS) – MI4. General Procedures

Inspection

-

NOTE: Procedure 1 — Ambient Temperature below 21 °C (70 °F).

NOTE: Proper A/C system diagnosis on a vehicle’s compressor is dependent on correct refrigerant system charge and tested in ambient temperatures above 21°C (70°F). Perform the following steps to achieve normal operating pressures.

Drive the vehicle or run the engine until it reaches normal operating temperature.

-

Set the A/C

system temperature to the highest possible temperature setting with the

dual function disabled (if equipped). Manually set the blower on HI. If

the vehicle has a fresh air/recirc button, set it to recirculation. If

the vehicle has an A/C switch or compressor on switch, set it to A/C OFF.

-

Close all the vehicle windows and doors.

-

Allow the vehicle to idle for 5 minutes.

-

Confirm the cabin temperature is above 24 °C (75 °F). Set the A/C switch or compressor on switch to MAX A/C ON.

-

Allow the vehicle to idle for 5 minutes.

-

Turn engine off and proceed to procedure 2 — ambient temperature between 21 °C (70 °F) and 38 °C (100 °F).

Inspection

NOTE: To perform an accurate test make sure the vehicle ambient temperature is 21 °C (70 °F) or above. Perform the following steps to achieve normal operating pressures.

-

NOTE: Procedure 2 — Ambient Temperature between 21 °C (70 °F) and 38 °C (100 °F)

Run the engine until it reaches normal operating temperature.

-

Connect the air conditioning service unit to the refrigerant system.

-

Set the A/C

system temperature to the lowest possible temperature setting with the

dual function disabled (if equipped). Manually set blower on HI. If the

vehicle has a fresh air/recirc button, set it to FRESH. If the vehicle

has an A/C switch or compressor on switch, set it to A/C ON.

-

Open all vehicle windows and leave the hood open for the test. Open the rear doors.

-

Confirm the compressor is operating and the engine

cooling fan(s) are operating or engaged. Allow the vehicle to idle until

the suction (low-side) and discharge (high-side) pressures are stable

or fluctuate in a range that repeats.

-

Record the ambient (shop) temperature.

-

Record the discharge pressure. If the pressure is fluctuating, record the average value.

-

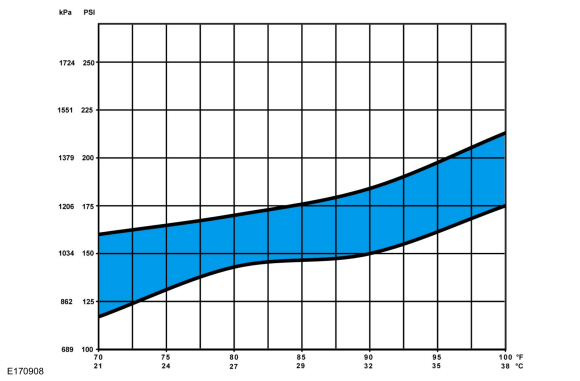

A/C

system, determine if the discharge pressure falls within the normal operating limits using the Normal Refrigerant Discharge Pressures 21 - 38 °C (70 - 100 °F) Ambient (30 - 60% Relative Humidity) chart below.

|

-

A/C

system, determine if the suction pressure falls within the normal operating limits using the Normal Refrigerant Suction Pressures 21 - 38 °C (70 - 100 °F) Ambient (30 - 60% Relative Humidity) chart below.

.jpg) |

-

Record the suction pressure. If the pressure is fluctuating, record the average value.

-

NOTE: Use the following table to guide diagnosis of the refrigerant system if operating pressures are outside normal limits.

High (Discharge) Pressure Low (Suction) Pressure Component — Causes High Normal to High - Condenser — inadequate airflow.

- Engine — overheating.

Normal to High Normal - Refrigerant overcharge — air in refrigerant.

Normal to Low High - A/C Compressor — low performance.

Normal to Low Normal to High - A/C suction line — partially restricted or plugged. a

Normal to Low Low - Low refrigerant charge — leak in system.

- A/C suction line — partially restricted or plugged. b

Erratic Operation or Compressor Not Running - Ambient Air Temperature (AAT) sensor — poor connection.

- A/C pressure transducer — poor connection.

- Evaporator temperature sensor — poor connection.

- Low refrigerant charge — leak in system.

Additional Possible Components or Causes Associated With Inadequate Compressor Operation - Compressor drive belt — loose

- Compressor clutch — slipping

- Clutch coil open — shorted, or loose mounting

- Control assembly switch — dirty contacts or sticking open

- Clutch wiring circuit — high resistance, open or blown fuse

- Compressor operation interrupted by engine computer

Additional Possible Components or Causes Associated With a Damaged Compressor - Incorrect clutch air-gap

- Suction accumulator — refrigerant oil bleed hose plugged

- Refrigerant leaks

a Low pressure reading will be normal to high if restriction is downstream of service access valve.

b Low pressure reading will be low if restriction is upstream of service access valve.

Inspection

-

NOTE: Procedure 3 — Ambient Temperature Above 38 °C (100 °F)

Run the engine until it reaches normal operating temperature.

-

Connect the air conditioning service unit to the refrigerant system.

-

Set temperature to the lowest possible temperature

setting with the dual function disabled (if equipped). Manually set

blower on HI. If the vehicle has a fresh air/recirc button, set it to

FRESH. If the vehicle has an A/C switch or compressor on switch, set it to A/C ON.

-

Open all vehicle windows and leave the hood open for the

test. Open the rear hatch and/or rear doors (if equipped).

-

Confirm the compressor is operating and the engine

cooling fan(s) are operating or engaged. Allow the vehicle to idle until

the suction (low-side) and discharge (high-side) pressures are stable

or fluctuate in a range that repeats.

-

Record the ambient (shop) temperature.

-

Record the discharge pressure. If the pressure is fluctuating, record the average value.

-

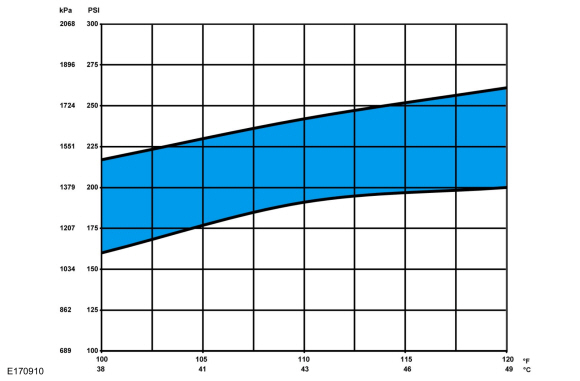

A/C

system, determine if the discharge pressure falls within the normal operating limits using the Normal Refrigerant Discharge Pressures 38 - 49 °C (100 - 120 °F) Ambient (15 - 40% Relative Humidity) chart below.

|

-

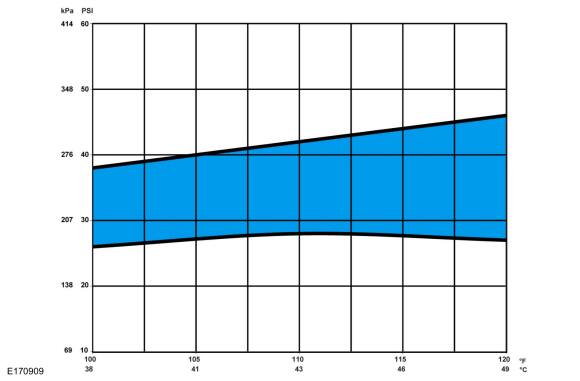

A/C

system, determine if the suction pressure falls within the normal operating limits using the Normal Refrigerant Suction Pressures 38 - 49 °C (100 - 120 °F) Ambient (15 - 40% Relative Humidity) chart below.

|

-

Record the suction pressure. If the pressure is fluctuating, record the average value.

-

NOTE: Use the following table to guide diagnosis of the refrigerant system if operating pressures are outside normal limits.

High (Discharge) Pressure Low (Suction) Pressure Component — Causes High Normal to High - Condenser — inadequate airflow.

- Engine — overheating.

Normal to High Normal - Refrigerant overcharge — air in refrigerant.

Normal to Low High - A/C Compressor — low performance.

Normal to Low Normal to High - A/C suction line — partially restricted or plugged. a

Normal to Low Low - Low refrigerant charge — leak in system.

- A/C suction line — partially restricted or plugged. b

Erratic Operation or Compressor Not Running - Ambient Air Temperature (AAT) sensor — poor connection.

- A/C pressure transducer — poor connection.

- Evaporator temperature sensor — poor connection.

- Low refrigerant charge — leak in system.

Additional Possible Components or Causes Associated With Inadequate Compressor Operation - Compressor drive belt — loose

- Compressor clutch — slipping

- Clutch coil open — shorted, or loose mounting

- Control assembly switch — dirty contacts or sticking open

- Clutch wiring circuit — high resistance, open or blown fuse

- Compressor operation interrupted by engine computer

Additional Possible Components or Causes Associated With a Damaged Compressor - Incorrect clutch air-gap

- Suction accumulator — refrigerant oil bleed hose plugged

- Refrigerant leaks

a Low pressure reading will be normal to high if restriction is downstream of service access valve.

b Low pressure reading will be low if restriction is upstream of service access valve.

Air Conditioning (A/C) Clutch and Air Conditioning (A/C) Clutch Field Coil. General Procedures

Air Conditioning (A/C) Clutch and Air Conditioning (A/C) Clutch Field Coil. General Procedures

Special Tool(s) /

General Equipment

412-001

(T71P-19703-B)

Remover, Compressor Pulley

Activation

Remove the A/C compressor. Refer to Air Conditioning A/C Compressor procedure in Group 412...

Reset the Outside Air Temperature Sensor Learned Values. General Procedures

Reset the Outside Air Temperature Sensor Learned Values. General Procedures

Configuration

NOTE:

The ambient air temperature sensor is a critical

component for correct Air Conditioning (A/C) and Heating, Ventilation,

and Air Conditioning (HVAC) system operation...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Audio Unit Antenna. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. AM Antenna. NOTE: The AM antenna is part of the rear spoiler. Replace the rear spoiler. Refer to: Rear Spoiler (501-08 Exterior Trim and Ornamentation, Removal and Installation)...

Lincoln Nautilus 2018-2026 Service Manual: Lane Keeping System - Overview. Description and Operation

Overview The Lane Keeping System (LKS) has three options to help the driver stay within their lane (lane keeping aid) and to provide lane keeping alert. The Lane Keeping System (LKS) utilizes the camera located in the IPMA to detect and track the road lane markings...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Power Outlet - Vehicles With: 110V Power Outlet

- Auto-Start-Stop

- Replacing the Rear Wiper Blades

- New on site

- Most important about car

Changing a Flat Tire

WARNING: If the tire pressure monitor sensor becomes damaged it may not function.

Note: The use of tire sealant may damage your tire pressure monitoring system and should only be used in roadside emergencies. If you must use a sealant, use the Tire Mobility Kit sealant. Replace the tire pressure monitoring system sensor and valve stem on the wheel by an authorized dealer after use of the sealant.

Note: The tire pressure monitoring system indicator light will illuminate when the spare tire is in use. To restore the full function of the monitoring system, all road wheels equipped with tire pressure monitoring sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply the brake hea