Lincoln Nautilus: Side Panel Sheet Metal Repairs / Rocker Panel Inner Reinforcement. Removal and Installation

Lincoln Nautilus 2018-2026 Service Manual / Body and Paint / Body and Paint / Side Panel Sheet Metal Repairs / Rocker Panel Inner Reinforcement. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Hot Air Gun | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055 |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Restore the vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

NOTE: The rocker panel inner reinforcement is made of martensite steel and cannot be sectioned. It must be replaced at factory seams.

-

Remove the following items:

-

Remove the rocker panel.

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Remove the B-pillar inner panel.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Remove the rocker panel.

-

Position aside the carpet and wiring harness in the repair area.

-

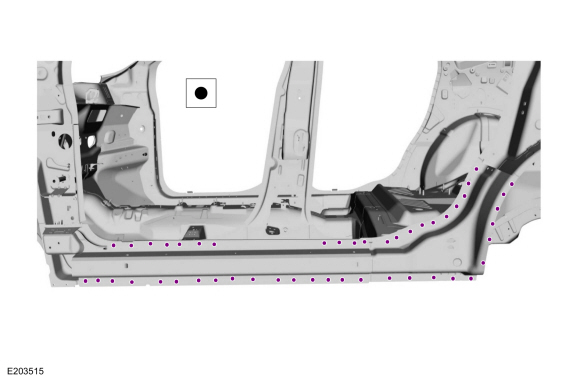

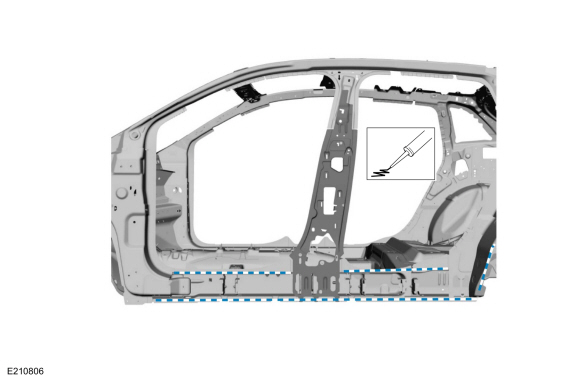

Remove the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

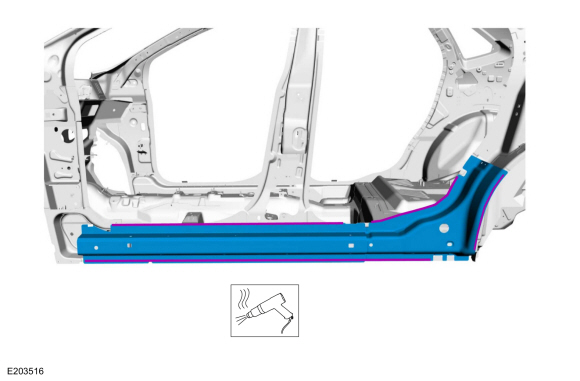

NOTE: Use of a heat gun may aid in softening the adhesive.

Remove the rocker panel.

Use the General Equipment: Hot Air Gun

|

Installation

NOTE: The rocker panel inner reinforcement is made of boron and cannot be sectioned. It must be replaced at factory seams.

-

Apply adhesive in the indicated areas.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

|

-

Install the rocker panel and resistance spot weld.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: Locking Pliers

.jpg) |

-

Complete weld with:

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Prime the repair area using a Ford approved paint system.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Install the following items:

-

Install the B-pillar inner panel.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the rocker panel.

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the B-pillar inner panel.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Position the wiring harness and carpet to original position.

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Perimeter Anti-Theft Alarm - Overview. Description and Operation

Overview The perimeter alarm system deters unauthorized entry into the vehicle by sounding the traffic and/or interior anti-theft alarm horn(s) and flashing all the turn signals and interior courtesy lamps. When an unauthorized entry occurs, the horn(s) and lamps activate for 30 seconds. After 30 seconds, the horn(s) stop sounding, but the lamps continue to flash for up to 5 minutes. The p..

Lincoln Nautilus 2018-2026 Owners Manual: California Proposition 65. Perchlorate. Replacement Parts Recommendation. Mobile Communications Equipment

California Proposition 65 WARNING: Operating, servicing and maintaining a passenger vehicle or off-highway motor vehicle can expose you to chemicals including engine exhaust, carbon monoxide, phthalates, and lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. To minimize exposure, avoid breathing exhaust, do not idle the engine e..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- USB Ports

- Folding the Exterior Mirrors - Vehicles With: Manual Folding Mirrors. Folding the Exterior Mirrors - Vehicles With: Power Folding Mirrors

- Interior Lamp Function. Adjusting the Instrument Panel Lighting Brightness. Ambient Lighting. Interior Lighting – Troubleshooting

- New on site

- Most important about car

Replacing the Rear Wiper Blades

Note: Do not hold the wiper blade to lift the wiper arm.

Remove the wiper blade.Copyright © 2026 www.linautilus.com