Lincoln Nautilus: Roof Sheet Metal Repairs / Roof Front Frame. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Factory welds may be substituted with resistance or MIG plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. MIG plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If required:

Dimensionally restore the vehicle to pre-damaged condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

If required:

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

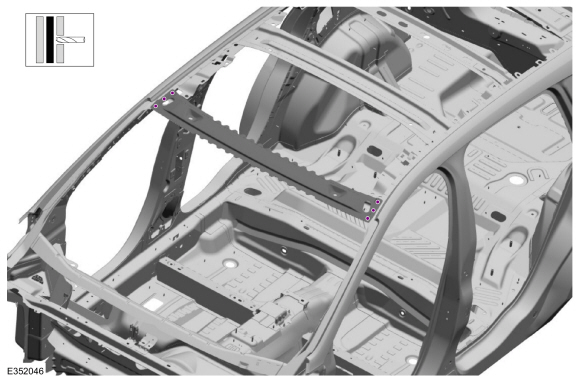

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the roof front frame.

.jpg) |

Installation

NOTE: Factory welds may be substituted with resistance or MIG plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. MIG plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

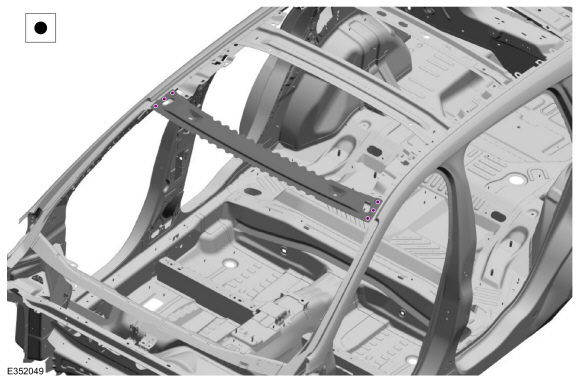

Install,properly position and clamp the roof front frame.

Use the General Equipment: Locking Pliers

.jpg) |

-

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work:

All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

If required:

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

Refer to: Roof Panel - Vehicles With: Panoramic Roof Opening Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Roof Panel - Vehicles With: Panoramic Roof Opening Panel. Removal and Installation

Roof Panel - Vehicles With: Panoramic Roof Opening Panel. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Scraper for Straight Edges

Spherical Cutter

Hot Air Gun

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B, Henkel Teroson EP 5055

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

..

Other information:

Lincoln Nautilus 2018-2026 Owners Manual: Switching Apple CarPlay On and Off

Enabling Apple CarPlay with USB Connect your device to a USB port. Follow the instructions on your device and the touchscreen. Note: Selecting "Enable Wireless CarPlay" on your device will prepare the device for wireless carplay when you re-enter the vehicle. Enabling Apple CarPlay with Wireless Pair your device to Bluetooth. Follow the instructions on your device and the touchscreen..

Lincoln Nautilus 2018-2026 Owners Manual: Evasive Steering Assist (If Equipped)

What Is Evasive Steering Assist If your vehicle is rapidly approaching a road user, evasive steering assist helps you steer around the road user. After you turn the steering wheel in an attempt to avoid a crash with the road user, the system applies additional steering torque to help you steer around the road user. After you pass the road user, the system applies steering torque when you tu..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Engine Oil Capacity and Specification - 2.0L

- Power Outlet - Vehicles With: 110V Power Outlet

- Locating the Pre-Collision Assist Sensors

- New on site

- Most important about car

Clearing the Garage Door Opener. Reprogramming the Garage Door Opener. Garage Door Opener Radio Frequencies

Clearing the Garage Door Opener