Lincoln Nautilus: Rear End Sheet Metal Repairs / Water Drain Panel. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the back panel.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the quarter panel.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Position the carpeting and wiring harness away from the working area.

-

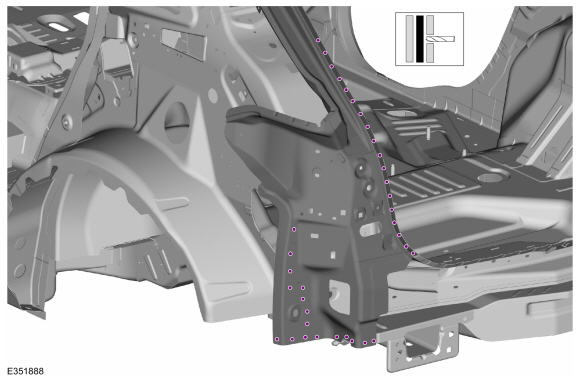

Remove the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the water drain panel.

.jpg) |

Installation

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Drill holes in the replacement panel for plug welding.

Use the General Equipment: 8 mm Drill Bit

|

-

Install,properly position and clamp the water drain panel.

Use the General Equipment: Locking Pliers

.jpg) |

-

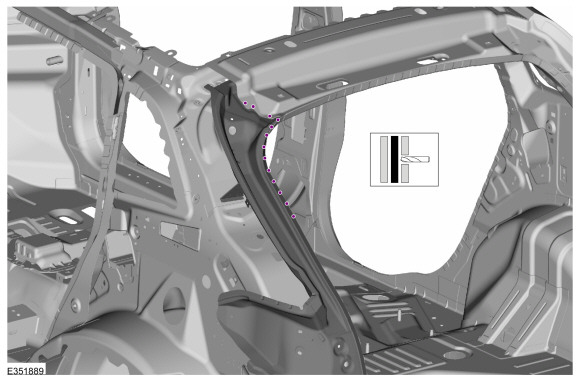

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

.jpg) |

-

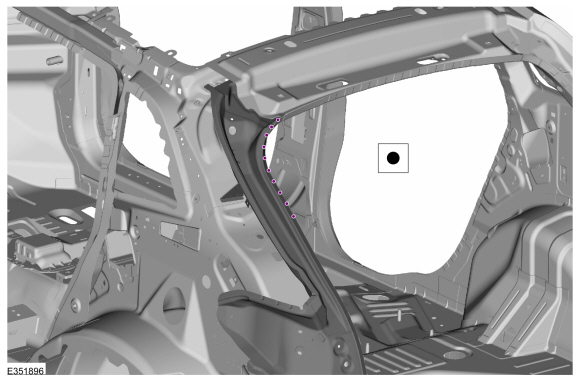

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

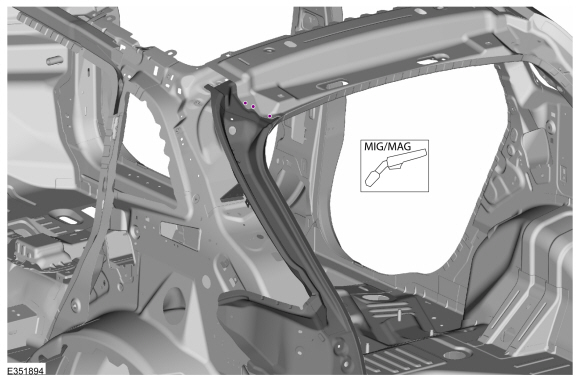

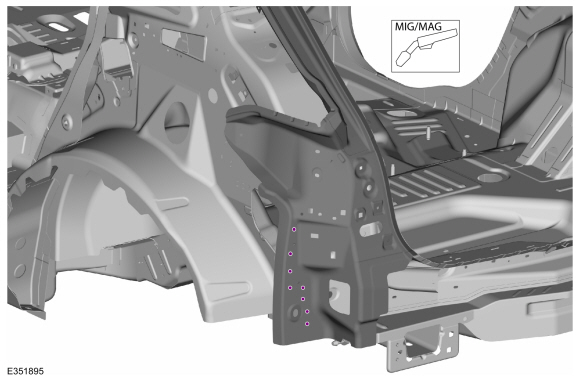

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reosition the carpeting and wiring harness to original location.

-

Install the quarter panel.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the back panel.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Rear Wheelhouse Outer. Removal and Installation

Rear Wheelhouse Outer. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Plasma Cutter

Air Body Saw

MIG/MAG Welding Equipment

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

Restore vehicle to pre-accident dimensions, if required...

Water Drain Panel Reinforcement. Removal and Installation

Water Drain Panel Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Left hand (LH) side shown, right hand (RH) side similar...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Trailer Module (TRM). Removal and Installation

Removal NOTE: This step is only necessary if the TRM is being replaced. Using a diagnostic scan tool, begin the PMI process for the TRM following the on-screen instructions. Remove the LH loadspace trim panel. Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation) ...

Lincoln Nautilus 2018-2026 Service Manual: Seatbelt Systems. Diagnosis and Testing

Symptom Chart(s) Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Preliminary Inspection Before diagnosing or repairing the seatbelt system, inspect the following items: Seatbelt webbing integrity (torn, frayed, cut or stretched) Seat..

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- Drive Mode Control

- Power Outlet - Vehicles With: 110V Power Outlet

- New on site

- Most important about car

Auto-Start-Stop

What Is Auto-Start-Stop

The system is designed to help reduce fuel consumption and CO2 emissions by stopping the engine when it is idling, for example at traffic lights.

Auto-Start-Stop Precautions

WARNING: Apply the parking brake, shift into park (P), switch the ignition off and remove the key before you leave your vehicle. Failure to follow this instruction could result in personal injury or death.

WARNING: Apply the parking brake, shift into park (P), switch the ignition off and remove the key before you open the hood or have any service or repair work completed. If you do not switch the ignition off, the engine could restart at any time. Failure to follow this instruction could result in personal injury or d