Lincoln Nautilus: Rear End Sheet Metal Repairs / Rear Wheelhouse Outer. Removal and Installation

Lincoln Nautilus 2018-2026 Service Manual / Body and Paint / Body and Paint / Rear End Sheet Metal Repairs / Rear Wheelhouse Outer. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Plasma Cutter | |

| Air Body Saw | |

| MIG/MAG Welding Equipment | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Restore vehicle to pre-accident dimensions, if required.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Remove the quarter panel as required.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Remove the quarter panel as required.

-

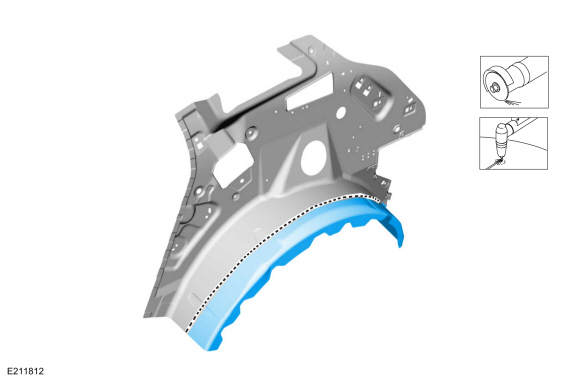

NOTE: Cutline shown as a general guideline for minor damage. Complete wheelhouse or inner quarter panel may be required, depending on extent of damage.

LH side shown, RH side similar. Cut the wheelhouse panel section and remove.

Use the General Equipment: Air Body Saw

Use the General Equipment: Spherical Cutter

.jpg) |

Installation

-

NOTE: LH side shown, RH side similar.

Cut section from the replacement part.

Use the General Equipment: Spherical Cutter

Use the General Equipment: Plasma Cutter

|

-

Install and weld the replacement section.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

.jpg) |

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the following items:

-

Install the quarter panel.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Install the quarter panel.

-

Reposition the carpeting and the wiring harness.

Rear Suspension Bracket Reinforcement. Removal and Installation

Rear Suspension Bracket Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTE:

LH side shown, RH side similar...

Water Drain Panel. Removal and Installation

Water Drain Panel. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Left hand (LH) side shown, right hand (RH) side similar...

Other information:

Lincoln Nautilus 2018-2026 Service Manual: Brake Caliper Anchor Plate. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the brake pads. Refer to: Brake Pads (206-03 Front Disc Brake, Removal and Installation). Remove the bolts and the brake caliper anchor plate...

Lincoln Nautilus 2018-2026 Owners Manual: Phone

Phone Precautions WARNING: Driving while distracted can result in loss of vehicle control, crash and injury. We strongly recommend that you use extreme caution when using any device that may take your focus off the road. Your primary responsibility is the safe operation of your vehicle...

Categories

- Manuals Home

- 1st Generation Nautilus Owners Manual

- 1st Generation Nautilus Service Manual

- USB Ports

- Locating the Pre-Collision Assist Sensors

- Normal Scheduled Maintenance

- New on site

- Most important about car

Replacing the Rear Wiper Blades

Note: Do not hold the wiper blade to lift the wiper arm.

Remove the wiper blade.Copyright © 2026 www.linautilus.com